John Deere 972 Flail Chopper

Hay Equipment

Your Preferred Location

Specifications

Chopper - Auger speed: |

246 rpm |

Chopper - Cutterhead speed: |

800 rpm |

Chopper - Cutting height: |

6.4-15.2 cm 2.5-6 in. |

Chopper - Cutting width: |

183 cm 72 in. |

Chopper - Drive system protection: |

Slip clutch protected |

Chopper - Height (with spout): |

312 cm 123 in. |

Chopper - Hitch adjustment: |

Yes, from tractor seat |

Chopper - Length: |

366 cm 144 in. |

Chopper - Number of knives: |

Rotor 42 (double edge) Cuttherhead 3 regular 3 optional |

Chopper - Operating width: |

312 cm 123 in. |

Chopper - PTO speed: |

540 rpm |

Chopper - Rotor speed: |

1,400 rpm |

Chopper - Tires: |

15-5.90, 4 PR |

Chopper - Transport width: |

287 cm 113 in. |

Chopper - Wagon hitches: |

Equal angle optional |

Chopper - Weight: |

849 kg 1,872 lb |

Key Specs - Cutting height: |

6.4-15.2 cm 2.5-6 in. |

Key Specs - Cutting width: |

183 cm 72 in. |

Key Specs - Drive system protection: |

Slip clutch protected |

Key Specs - PTO speed: |

540 rpm |

Key Specs - Transport width: |

287 cm 113 in. |

Key Specs - Weight: |

849 kg 1,872 lb |

Cutting width of 1.8 m (6 ft) for good productivity

Cutting width

Cutting width

With its 1.8-m (6-ft) cutting width, the 972 Flail Chopper handles a variety of jobs:

- Makes excellent grass silage

- Shreds and spreads corn and cotton stalks

- Chops light brush

- Makes silage of beet tops

- Clips pastures

Lower initial costs and simple, rugged construction make the 972 easy to buy and maintain.

Tractor hookup is fast and easy

Category 2 hitch

Category 2 hitch

The hitch is Category 2, with hitch plates attached by bolts and bushings. The tongue is made of 3-in. x 5-in. PTR for higher strength.

The tongue can be adjusted from the tractor seat.

A screw-type jack makes hitching up the 972 Flail Chopper fast and easy.

Welded mainframe is 40 percent thicker and offers higher structural resistance

Mainframe

Mainframe

The mainframe is welded instead of bolted:

- The welded design offers higher structural resistance.

- For longer life, the hood is 40 percent thicker than the hood used on the discontinued 16A Flail Chopper.

Discharge spout can be adjusted from the tractor seat

Easy adjustment from tractor

Easy adjustment from tractor

Discharge spout

Discharge spout

The discharge spout mechanism allows the operator to easily adjust the direction in which the forage is thrown and, at the same time, adjust the speed at which the material is being ejected.

- The material deflector has independent movement from the rotation lever and is adjustable for different positions.

- The spout mechanism is heat-treated, which ensures a longer life of its components. The spout rotation is done through a lever, within reach of the operator from the tractor.

- A steel wear sleeve (attachment) extends the life of the spout.

- The vertical and horizontal extensions (attachments) evenly fill the larger or taller wagons.

Gauge wheels are very easy to change

Rear axle

Rear axle

The rear axle is made of 102x102-mm (4x4-in.) steel. This axle has two hitch supports:

-

The left-hand support is used to attach the wagon during operation, while the right-hand support is used to hook the wagon during transport when it is necessary to have it in line with the chopper and the tractor.

Two wheels with 5.90x15 4 PR tires are included as standard equipment.

Changing wheels

Changing wheels

Changing the wheels and tires is a very simple operation.

The square axle of the chopper has jackstand supports that help when changing the tires.

With the chopper hooked up to the tractor, the jackstand can be placed on either support, left or right, as required.

Auger and cutterhead provides better delivery of material

Auger

Auger

The speed of the auger is 300 rpm, which provides better delivery of material into the cutterhead.

The design of the door allows easy access to the auger. There are three reinforced hinges to prevent breakage.

For increased convenience, a cover over the chain on the right-hand side can be removed when service is necessary.

Cutterhead

Cutterhead

Three rotary knives are included in the cutterhead as base equipment, and a set of three additional rotary knives can be ordered.

- Knives are adjustable to provide longer life.

- Three fan blades and three fan plates located between the knife supports are installed to increase the efficiency of forage ejection.

The lower side of the cutterhead has 56 percent thicker steel than the 16A cutterhead for longer life.

Its improved design allows easy installation and removal.

Double-edged rotor knives can be reversed to increase life

Double-edged rotor knives

Double-edged rotor knives

The rotor design has two rows of knives that allow a uniform cut of the forage:

- The rotor speed is 1366 rpm

- The cutting width is 1.8 m (6 ft)

The cutting height can be adjusted to obtain a minimum of 6.4 cm (2.5 in.) or a maximum of 18.4 cm (7.25 in.) with a lever or an optional hydraulic cylinder.

The mounting system of the knives allows them to swing back when they hit stones or other obstacles and to automatically return to their normal position without interrupting the chopping operation.

The rotor has 42 heat-treated knives. They are double edged so they can be reversed, increasing their longevity.

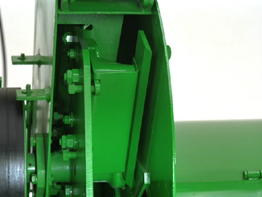

Drivetrain with slip clutch protects the drive system of the chopper

Slip clutch

Slip clutch

The slip clutch is designed to protect the components of the drive system of the chopper.

The slip clutch releases the load and reengages automatically, protecting the components when there is an overload or obstruction, avoiding damage to or breakage of the chopper parts.

Overrunning the clutch, integral with the slip clutch, releases the rotating parts, disconnecting the tractor power take-off (PTO).