John Deere 525D Draper

Windrowers

Your Preferred Location

Specifications

Auxiliary top auger - Type: |

Optional: factory-installed cross-pea auger |

Cutterbar - Cut width (length): |

7.6 m 25 ft |

Cutterbar - Cutterbar tilt: |

Hydraulic, adjustable from cab |

Cutterbar - Knife drive: |

Two hydraulic motors and two knife drives |

Cutterbar - Knife speed: |

1,100 to 1,440 spm |

Cutterbar - Stroke length: |

84 mm 3.3 in. |

Cutterbar - Type: |

SCH® Easy Cut with roller guides, spring steep guards, and bolted sections Standard: single knife or dual knife |

Dimensions - Operating width (field): |

7.6 m 25 ft |

Dimensions - Transport height: |

2.44 m 8 ft |

Dimensions - Transport length, hitch extended: |

9 m 29.6 ft |

Dimensions - Transport width (reel fully retracted): |

2.6 m 8.5 ft |

Draper and decks - Belt width: |

V-guided draper belt: 106.7 cm 42 in. |

Draper and decks - Deck extensions: |

Optional, dealer-installed deck extensions: 35.6 cm 14 in. |

Draper and decks - Deck tilt: |

Standard |

Draper and decks - Delivery opening height: |

205.7 cm 81 in. |

Draper and decks - Delivery opening width: |

Delivery, double swath opening: 137.2 cm 54 in. Delivery, single swath opening: 203.2 cm 80 in. |

Draper and decks - Draper drive: |

Two hydraulic motors |

Draper and decks - Operating speed: |

0 to 232 m/min 0 to 760 fpm |

Draper and decks - Remote canvas speed control: |

Standard |

Draper and decks - Speed control: |

Adjustable in windrower cab |

Gauge wheels and transportation - Gauge wheels: |

Adjustable castoring gauge wheel optional |

Gauge wheels and transportation - Integrated slow speed transport system: |

Self-contained transport, including hitch, jack and axle, is conveniently stored on the swather table |

Key Specs - Belt width: |

V-guided draper belt: 106.7 cm 42 in. |

Key Specs - Cut width (length): |

7.6 m 25 ft |

Key Specs - Cutterbar - Type: |

SCH® Easy Cut with roller guides, spring steep guards, and bolted sections Standard: single knife or dual knife |

Key Specs - Fingers: |

Plastic |

Key Specs - Reel type: |

Hydraulic |

Key Specs - Transport length, hitch extended: |

9 m 29.6 ft |

Reel - Diameter: |

1118 mm 44 in. |

Reel - Fingers: |

Plastic |

Reel - Height control: |

Hydraulic, adjustable from cab |

Reel - Number of bats: |

Six |

Reel - Reel fore and aft: |

Hydraulic, adjustable from cab |

Reel - Reel lift: |

Hydraulic, adjustable from cab |

Reel - Reel type: |

Hydraulic |

Reel - Speed control: |

Hydro handle, in cab |

Weight - Approximate weight (base platform with reel): |

2280 kg 5026 lb |

Weight - Approximate weight (base platform without reel): |

1036 kg 2869 lb |

Draper hydraulic pump control logic delivers constant header speed

500D Draper on windrower

500D Draper on windrower

The draper hydraulic pump control maintains knife, belt, and reel speeds regardless of engine rpm changes.

- Results in uniform cut quality and windrow formation regardless of the terrain or engine load

- Reduces crop loss or shatter

John Deere parts and service support provide uptime for a timely harvest

Sales, parts, and service support from a local John Deere dealer offer overnight parts delivery and a well-trained support staff.

Interchangeable with John Deere rotary platforms

500D Draper and interchangeable rotary platform

500D Draper and interchangeable rotary platform

500D Draper has an interchangeable rotary platform:

- Interchangeable on W235 or W260 traction units in 30 minutes or less

- Growers can use one traction unit for harvesting both small grains and hay

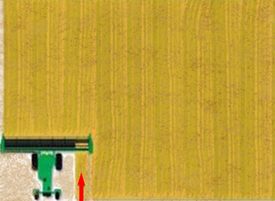

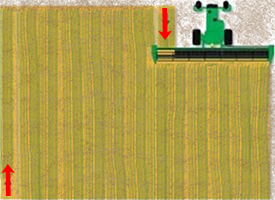

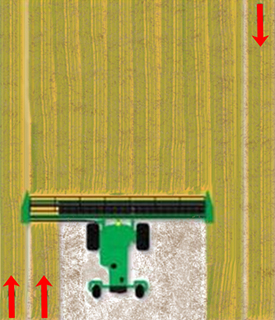

Hydraulic deck shift (double swath package)

John Deere 525D, 530D, and 536D Drapers can windrow out of the center, right, or left ends of the draper with the press of a button using the hydraulic shift option (double swath package).

- Larger windrows to match combine or self-propelled forage harvester

- Match narrower-width drapers with higher-capacity harvesting

- Place higher-density windrows in front of harvesters when yields are low

- Discharge two windrows side by side for uniform combine or forage harvester feeding

First pass with right discharge

First pass with right discharge

Second pass with right discharge

Second pass with right discharge

Third pass with left discharge

Third pass with left discharge

Center discharge

Center discharge

Higher productivity with center-driven belts

Center-driven belts

500D Draper on W235 Windrower

500D Draper on W235 Windrower

- Deliver increased torque

- Enable greater productivity with minimal belt slippage

- Increase performance in heavy crop conditions

Red circles point out the location of the belt drive motors

Red circles point out the location of the belt drive motors

- Draper belts on the 500D are driven from the center of the platform

- Delivers increased belt performance compared to drapers with end-driven belts

Belt drive motors

Motor driving the left-hand belt

Motor driving the left-hand belt

Motor driving the right-hand belt

Motor driving the right-hand belt

Due to the motors pulling the belt (instead of pushing in an end drive system), there is less slack in the belt. This delivers an increase in belt torque.

As a result, producers will experience minimal belt slippage and increased performance in heavy crop conditions due to the center-driven belt system.

Strong, positive-feeding reel handles all crop conditions

500D Draper

500D Draper

The 500D Series includes an improved reel that increases durability in heavy crop conditions.

500D Draper teeth

500D Draper teeth

- Easy reel tooth replacement is done with a 90-degree turn with a wrench. It will allow the reel tooth to be removed and replaced.

- Additional teeth can be added at any location along the extruded tooth bar.