John Deere 696 Rotary Harvesting Unit

Hay Equipment

Your Preferred Location

Features

-

Number of Rows: 6

-

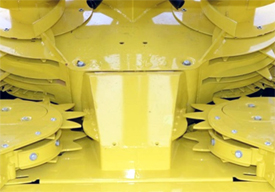

Drum Configuration: 6-Small Drums

-

Width: 14.8 ft (4.5 m)

Specifications

Key Specs - Rotary harvesting unit: |

Length 1.5 m 5.25 ft Overall width 4.5 m 14.75 ft Height 1.4 m 4.6 ft Operating width 4.5 m 14.75 ft Transport width 3 m 9.8 ft Weight 2,025 kg 4,464 lb |

Revolution rating calculated with forage harvester at a standstill without load - Cutting blades for gathering drum: |

|

Revolution rating calculated with forage harvester at a standstill without load - Gathering drum: |

|

Rotary harvesting unit - Height: |

1.4 m 4.6 ft |

Rotary harvesting unit - Length: |

1.6 m 5.25 ft |

Rotary harvesting unit - Operating width: |

4.5 m 14.75 ft |

Rotary harvesting unit - Overall width: |

4.5 m 14.75 ft |

Rotary harvesting unit - Transport width: |

3 m 9.8 ft |

Rotary harvesting unit - Weight: |

2,025 kg 4,464 lb |

Lengthwise feeding for optimal chopping quality

Bundled, lengthwise feeding toward the feed rolls

Bundled, lengthwise feeding toward the feed rolls

Even feeding of the harvested crop bundled lengthwise to the chopper unit of the self-propelled forage harvester (SPFH) is crucial for an even cut. Only even, lengthwise feeding allows for the full use of the power installed on the SPFH.

Benefits:

- Bundling of lengthwise stalks is the basis for perfect cutting.

6 row with three rings of teeth-feeding crops to the SPFH

6 row with three rings of teeth-feeding crops to the SPFH

8, 10 and 12 row with two rings of teeth-feeding crops to the SPFH

8, 10 and 12 row with two rings of teeth-feeding crops to the SPFH

Two angled feed drums push the crop toward the feed rolls of the SPFH. The size of the feed drums depends on the size of the header; the 6-row headers feature three rings that push the crop in the feed rolls of the SPFH. The 8-, 10-, and 12-row headers feature a lower version with only two rings.

Benefits:

- The feeding drum size, depending on the working width, provides the necessary space to use 10- and 12-row headers, which allows for the operator to feed larger crop bundles to the SPFH.

Intake fingers and gatherer drums for secure crop guidance

Intake fingers push every plant into the gatherer drum

Intake fingers push every plant into the gatherer drum

After the fast rotating blades cut the crop, the intake fingers push the plants into the gatherer drums that rotate in the same direction at low speeds. Every plant is pushed into the teeth of the gatherer drum. The specially designed shape of the teeth ensures that both small and large plants are conveyed in a secure way.

In the machine, the plants are taken off the back of the gatherer drum by scrapers. Depending on the width of the header, they are forwarded to the cross-feed drums or immediately fed into the angled feed drums in the middle of the machine.

Key feature:

- Every plant is individually and securely pushed into the gatherer drum (Performance).

Open design keeps the header going

With the new generation of the small drum headers, leading performance is proven. Due to feed availability pressures, the variety of plants and harvesting conditions becomes more and more challenging. The investment into a special head is expensive. The John Deere small-drum header is a good alternative to harvest a variety of crops.

The most challenging is the optimization of the crop flow in the header. An open construction was the solution. All drum scrapers or holders of divider points are positioned out of the crop flow. An accumulation or blocking of weeds and leaves will be avoided.

Open design dirt will fall out of the header

Open design dirt will fall out of the header

Benefits:

-

The open design ensures the header is self-cleaning for cleaner silage.

-

The open design is more reliable because dirt does not build up in the header.

Fast-turning saw blades cut all kinds of crop

Saw blades with changeable segments

Saw blades with changeable segments

The saw blades of John Deere rotary crop headers cut quickly and thoroughly at a high speed of rotation. As the fast-turning blades cut the full width, crops can be harvested regardless of the row spacing. Thanks to this row-independent harvesting technology, the field can be worked from any side, which is particularly important for down crop.

The fast-turning saw blades allow crops with a lot of weeds to be harvested easily. Besides maize, a wide range of crops such as sorghum, whole crop silage, oilseed, canola, pampas grass, and miscanthus can be harvested.

Key features:

- Fast turning saw blades can cut in difficult harvesting conditions to give the operator increased uptime.

- Headers can be used in various stemmed crops and there is no need for extra headers, which saves on the cost of operation.

Improved ground following with third Advanced Header Control (AHC) sensor

AHC sensor

AHC sensor

Experience improved ground following with the third AHC sensor, available as a bundle for the middle of the machine.

- Better following of ground contours

- Prevents wide headers from diving into plough furrows, for example

- Less wear