John Deere 1890 No-Till Air Drill

Air Drills

Your Preferred Location

Features

-

Row Spacing: 7.5-in. (190-cm) 10-in. (254-cm)

-

Fertilizer Placement: In Furrow

-

Transport Width: 14 ft. 4 in., 18 ft. 4 in., /18 ft. 10 in.

-

Working Width: 30 ft., 36 ft., /40 ft., 42 ft., /50 ft., 60 ft.

-

Opener: New ProSeries

Specifications

Dimensions - Available ballast: |

1386 (28+14 x 100) kg 2800 (28+14 x 100) lb |

Dimensions - Clearance from rank to rank: |

133.99 cm 52.75 in. |

Dimensions - Frame: |

Cross members 102 x 152 mm 4 x 6 in. End tubes 51 x 152 mm 2 x 6 in. Hitch 76 x 152 mm 3 x 6 in. |

Dimensions - Overall length: |

7.49 m 24.58 ft, in. |

Dimensions - Road clearance: |

21.6 cm 8.5 in. |

Dimensions - Transport height: |

3.63 m 11.92 ft |

Dimensions - Transport width: |

4.37 m 14.33 ft |

Dimensions - Weight before ballast: |

7711, 6759 kg 17000, 14900 lb |

Key Specs - Number of ranks: |

two |

Key Specs - Openers: |

Style Single disk-beveled edge Rank lock-up Yes Diameter 45.72 cm 18 in. Down pressure Hydraulic |

Key Specs - Spacing: |

19.05, 25.4 cm 7.5, 10 in. |

Key Specs - Working widths: |

9.14 m 30 ft |

Openers - Depth control: |

Description Gauge wheel beside disk Gauge wheel size 11.43 x 40.64 or 7.62 x 40.64 cm 4.5 x 16 or 3 x 16 in. Range 1.27 to 8.89 cm 0.5 to 3.5 in. Increments 0.64 cm 0.25 in. |

Openers - Disk: |

Diameter 45.72 cm 18 in. Angle 7 degree (angle) |

Openers - Down pressure: |

Style Active hydraulic-patented Hydraulic |

Openers - Furrow closing: |

Description Trailing wheel on 20-degree vertical angle, 7-degree horizontal angle Size 2.54 x 30.48 cm 1 x 12 in. Material Cast iron Down force 26 to 43 lb 12 to 20 kg Standard |

Openers - In-Furrow press wheel: |

Material Rubber on plastic wheel Packing force 5 to 45 lb 2.3 to 21 kg Standard |

Openers - Rank lock-up: |

Yes |

Openers - Style: |

Single disk-beveled edge |

Sizes - Number of ranks: |

Two |

Sizes - Number of sections: |

Three |

Sizes - Spacing: |

19.05, 25.4 cm 7.5, 10 in. |

Sizes - Working widths: |

9.14 m 30 ft |

Tires - Mainframe standard: |

(8) 11L-15, 10PR |

Tires - Wheel spacing, center frame: |

|

Tires - Wings standard: |

(4) 11L-15, 8PR |

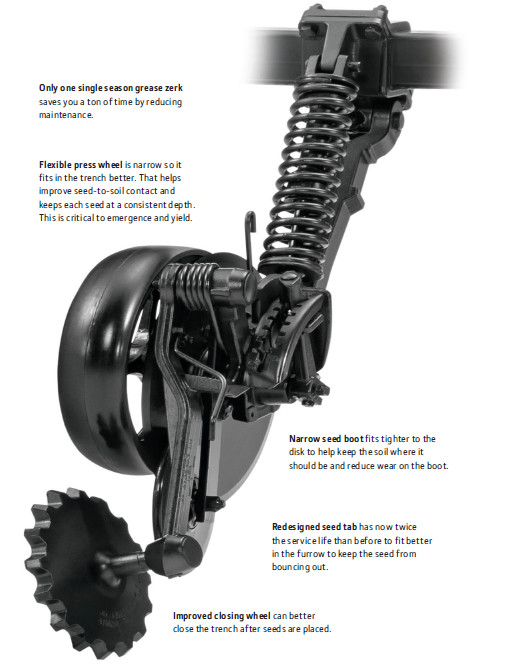

No-till opener seeding with minimal maintenance from the ProSeries™ Opener

ProSeries Openers

ProSeries Openers

The ProSeries Opener is John Deere’s most advanced opener for your seed and separate fertilizer placement. When it comes to seeding precision, consistent seed depth, and uniform emergence in virtually all field conditions, you can superSEED your expectations with ProSeries.

Two of the three daily grease points have been removed. The third grease point is now a yearly interval. The narrow seed boot travels behind the shadow of the blade, causing less soil disturbance. When attaching the boot to the shank, the bolt has been replaced with a flag pin. Now the flag pin is the wear point, not the casting, reducing overall maintenance. The seed press wheel is also redesigned; it has a narrow profile, a double-wall bearing, and is made of a flexible material. Lastly, the seed tab is UV resistant and profiled similar to the trench. There is also the added option of the serrated closing wheel.

ProSeries Openers are in base equipment on all 1890 and N500F Separate Fertilizer Placement (SFP), N500C, 1990 Central Commodity System (CCS™), and 1590 Air Drills.

The ProSeries Openers:

- Work not only in no-till conditions, but also in minimum or reduced-till conditions

- Provide 51 mm (2 in.) of free travel in the opener before spring down pressure takes over

- Benefit: allows the opener to move over uneven ground conditions and minimize the chance of the gauge wheels bulldozing soil in soft or mellow conditions

- The opener spring travels a maximum of 203-mm (8-in.) up or 150-mm (6-in.) down before the hydraulics react to uneven seedbeds

Integration advantages of Deere tractor, cart, tool and technology

To win big in small grains, it takes a seeding solution that superseeds your expectations. John Deere delivers with a complete line of everything you need – and the sizes you want – to seed for success. Air-hoe drills. Commodity air carts. No-till air drills. Openers. Fertilizer attachments. Central commodity systems. Box drills. Plus precision ag technology to stretch your productivity to higher levels. But it’s far more than iron and technology. It’s the exceptional agronomic know-how and unsurpassed dealer support in all phases of production to keep you running. With our latest additions to equipment and openers, our seeding solutions deliver the next-generation performance you need to help you reach the full potential of each seed. That’s our commitment to you.

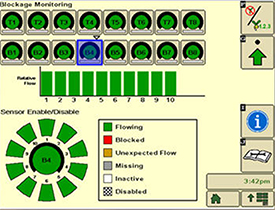

Confidence in rates from row to row with RelativeFlow™ Blockage sensing

With the RelativeFlow blockage sensing, operators can see the flow rate of both seed and fertilizer from inside the tractor cab. Sensors on all primary towers and secondary hoses monitor the relative product flow, giving you a better view of the flow rate of both seed and fertilizer from the cart to the opener from inside your tractor cab. This exclusive technology can help you identify any problems before potential blockage occurs.

RelativeFlow Blockage is available on the following models:

- P540 - 12.2-m (40-ft)

- P556 - 17.1-m (56-ft)

- P576 - 23.2-m (76-ft)

- N500C - all widths

- 1890 - 15.2-m (50-ft) and 18.3-m (60-ft)

- N530F - 9.1-m (30-ft)

- N540F - 12.2-m (40-ft)

- N543F - 13.1-m (43-ft)

- N560F - 18.3-m (60-ft)

RelativeFlow Blockage is compatible with hydraulic drive carts for model year 2014 and newer 1910, model year 2013 and newer 550 Carts, C650 and C850 Air Cart.

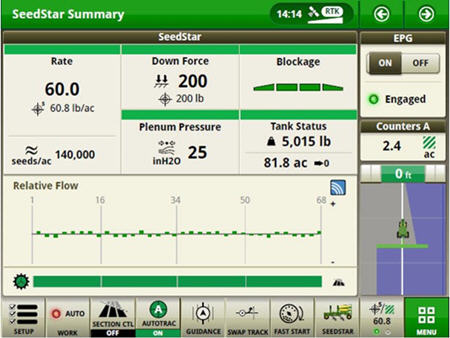

Below are the GreenStar™ 3 2630 Display screens for the blockage monitoring system. For complete details and information, see the owner’s manual.

Blockage monitoring screen on GreenStar™ 3 2630

Blockage monitoring screen on GreenStar™ 3 2630

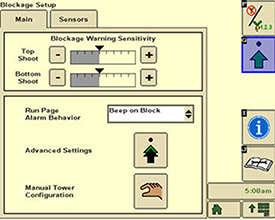

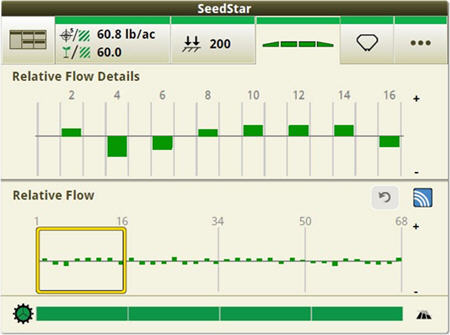

The RelativeFlow sensing chart shows the amount of flow through each sensor on the selected tower. Sensitivity for the blockage system can be adjusted if desired, as shown below.

Blockage monitoring screen on GreenStar 3 2630

Blockage monitoring screen on GreenStar 3 2630

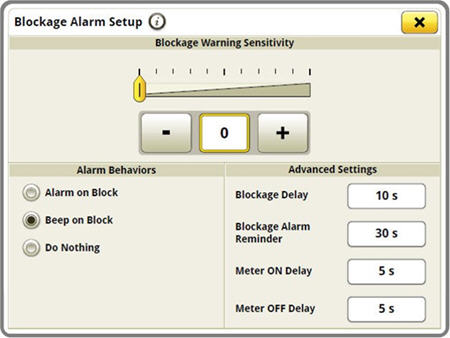

Blockage warning sensitivity allows the producer to set and change the sensitivity of the sensors to meet their preferences. Increasing the sensitivity means the system is more likely to show a false blockage, while less sensitivity means the system is more likely to miss a blockage.

Multiple run-page alarm behavior options are available for selection.

Blockage monitoring screen on GreenStar 3 2630

Blockage monitoring screen on GreenStar 3 2630

Below are the Gen 4 display screens for the blockage monitoring system on the N500C.

For complete details and information reference, the owner’s manual.

RelativeFlow Blockage configured run page

RelativeFlow Blockage configured run page

The SeedStar™ system run page displays the five major run settings. Clicking on any of the tiles will take an operator to that specific page (shown below).

Operators can zoom into flow details by meter section when selecting blockage tiles

Operators can zoom into flow details by meter section when selecting blockage tiles

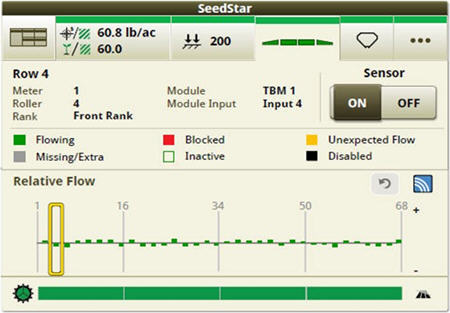

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

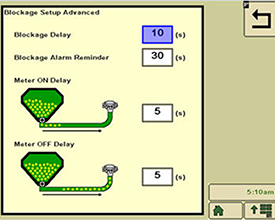

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

Blockage alarm delays can be set up by clicking on the advanced settings button from the blockage set-up screen.

- A blockage delay is how long a blockage should occur before an alarm is sounded.

- The blockage alarm reminder is how often the alarm should sound when a blockage occurs.

- The meter on delay is the time from when the meter is turned on until the blockage sensor should start monitoring for blockage.

- The meter off delay is the time from when the meter is turned off until the blockage sensor should start monitoring to verify no flow.

For more detailed information, see the owner’s manual.

Air tools with Relative Flow Blockage are not compatible with 1910 air carts with ground drive.