Kuhn SW 4014

| Make | Kuhn |

| Model | SW 4014 |

| Type | Square Bale Wrappers |

Your Preferred Location

Description

The versatile KUHN SW 4014 square and round bale wrapper provides fast, cost efficient and operator-friendly wrapping. The laser-guided, patented AutoLoad function detects, loads, wraps and unloads bales automatically, creating a more ergonomic and stress-free working environment. This wrapper features a solid design and a hydraulic sliding frame that allows unique drive-through operation. This provides the ability to widen the wrapper for easy bale loading, outstanding stability and unmatched visibility of the wrapping process. The Autoswitch function enables the wrapper to fold from transport position into field position with a single push of a button on the ISOBUS terminal. ISOBUS, combined with KUHN’s IntelliWrap™ provides excellent distribution of the film applied around each bale with further film savings.

Models

Optimal Versatility

The SW 4014 is capable of wrapping large square and round bales up to 3,307 pounds. Wrapping of round bales is possible without any additional equipment or mechanical adjustments. All predefined bale dimensions can easily be selected via the monitor.Unique “Drive Through” Design

Thanks to its solid design, with incorporated hydraulic sliding frame, an extremely wide track is achieved for outstanding stability of the machine. This unique “drive through” operation enables easy loading of the bale and excellent visibility of the wrapping process. The Autoswitch function enables the wrapper to fold from transport position into field position with a single push of a button on the ISOBUS terminal. The wrapper is 13’ in field position and folds to a narrow 8’ for transport.Exceptional Bale Handling

The smart “drive through” design of the SW 4014 guarantees easy (un)loading of the bales, front- and backwards, even when dropped in hard-to-reach locations. All bales are (un)loaded without the risk of damaging or soil contamination because of the two patented* pair of steel rollers. To prevent film damage during transport, the SW 4014 is fitted with large wheel covers.Easy Maintenance and Accessibility

The large side doors of the SW 4014 provide excellent accessibility for maintenance. Furthermore you can open the top cover and side doors without the need of tools. The SW 4014 can be equipped with an optional LED work light to have a better view on the wrapping process in the dark.Non-Stop Wrapping With Autoload

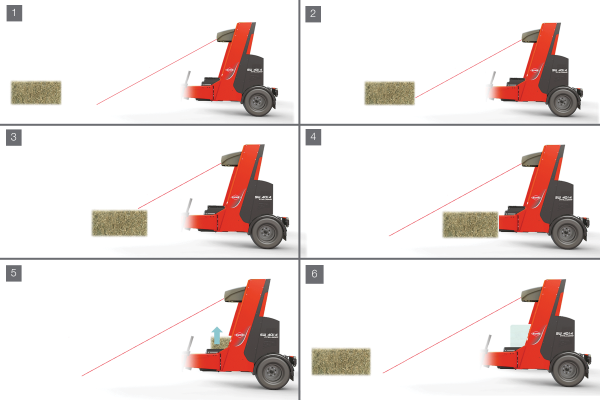

The innovative AutoLoad function provides non-stop, fully automatic loading, wrapping and unloading of square- and round bales without interference from the driver. AutoLoad detects approaching bales, automatically scans the length of the bale and sets the loading arms into pre-load position, resulting in accurate loading, wrapping and unloading of the bale on the go. This leads to increased overall capacity and creates a more ergonomic and stress-free working environment during a long working day.How Does It Work?

AutoLoad function is based on Category II Laser technology. First the laser sensor, situated inside the top cover at the front side of the machine, is scanning the area ahead of the bale wrapper. In addition, a wheel sensor is placed on the left wheel which measures the speed and distance toward the bale. Laser sensor is measuring ground level. Laser sensor has detected the bale. Laser sensor has detected the edge of the bale. Bale length measurement is starting by counting pulses on wheel sensor. Loading arms move to pre-load position (based on pre-defined bale width). Laser sensor has detected the end of the bale. The bale length is known. Depending on the driving speed, the loading arms are activated at the right time to load the bale in the center of the rollers. While wrapping, it is possible to drive already to the next bale. In case bales are dropped in ditches, under fences or even in corners of the field, the SW 4014 AutoLoad still allows you to load bales manually, forwards and backwards.Twin-Satellite Design

The twin-satellite design ensures high-speed wrapping. The standard pre-stretchers, which each hold a 30” (750 mm) roll, are made of aluminum to avoid build-up of tack from the film. Both outer ends of the aluminum rollers are cone-shaped to maintain the optimum width of the film and reduce the risk of film tear. The special ribbed profile of the aluminum rollers keeps air and water away from the film. The location of the pre-stretchers makes it very easy to change the film rolls. The standard pre-stretch of 60% is reached by a low-maintenance and low-noise gear transmission. The positioning of the patented shorter top rollers allow the film roll holders to be positioned as low as possible. As a result, the film is wrapped closer to the center of the bale with less wrinkling, ensuring an optimum oxygen barrier for excellent silage quality. Once the desired number of film layers has been applied, the film is then held firmly and cut by two “scissor-type” film cutters. Due to this design, the film is caught across the full width. The film is held with a clamp, gathered into one solid rope and then cut before the bale is unloaded. The clamp firmly holds the film ready for the next bale.IntelliWrap

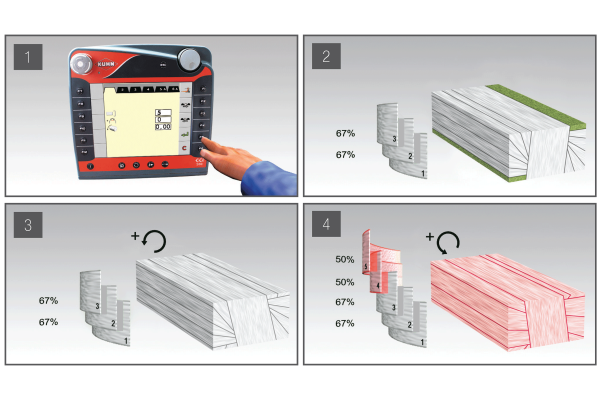

Greater management and control of the wrapping process can be achieved by our unique IntelliWrap™. IntelliWrap uses sophisticated electronics and hydraulics to monitor the wrapping process and continuously controls the film overlap, allowing total flexibility. Depending on local circumstances, crop conditions and storage periods the amount of film layers (4, 5, 6, 7, 8, 9...) can simply be adjusted. An excellent distribution of the film around the bale and precise overlap of the film provides maximum efficiency and increased silage quality. 1. Selection of five film layers 2. The bale is covered with three layers and 67% overlap 3. Increasing of the bale rotational speed 4. Final two layers with 50% overlapSpecifications

- Bale alignment adjustment: Hydraulically shift wrapper for proper alignment with bale

- Bale auto-levelling for wrapping and unloading: Standard

- Control: No monitor standard; optional CCI 50, CCI 800 or CCI 1200 ISOBUS monitor

- Film pre-stretcher: Standard 30'' (76 cm)

- Hitch: Cat. 2 swivel headstock

- Kit for 1/2 table speed to work with one pre-stretcher: Standard on monitor (activated automatically if equipped with optional film break sensor)

- Large square bale size - width x height x length: 2x3 (0.6 x 0.9 m), 3x3 (0.9 x 0.9 m), 3x4 (0.9 x 1.2 m), or 4x4 (1.2 x 1.2 m) bales up to 6'6'' (2 m) long

- Length: Without PTO driven hydraulics: 15'5" (4.7 m) With PTO driven hydraulics: 17' (5.1 m)

- Loading system: Twin roller arms

- Machine net weight: 6,220 lbs (3,003 kg)

- Maximum bale weight: 3,300 lbs (1,500 kg)

- Output and pressure required: Standard 11-16 gpm at 2,600 psi

- Pre-stretch ratio: Standard 60% - Optional 70%

- PTO driven hydraulics: Optional

- Required tractor hydraulic connections: 1 SA with 3/4'' free turn

- Round bale size - width x diameter: (4'-5') x (3'-4'10'') ((1.2-1.52 m) x (0.9-1.5 m))

- Satellite arm: Twin satellite arm

- Tires: Standard 380/55X17

- Transport height: 9'2'' (2.8 m)

- Transport width: 8'2" (2.5 m)

- Wrapping table: Electronic controlled 2x2 roller pair

Links

Copy Set

Optimal Versatility

The SW 4014 is capable of wrapping large square and round bales up to 3,307 pounds. Wrapping of round bales is possible without any additional equipment or mechanical adjustments. All predefined bale dimensions can easily be selected via the monitor.

Unique “Drive Through” Design

Thanks to its solid design, with incorporated hydraulic sliding frame, an extremely wide track is achieved for outstanding stability of the machine. This unique “drive through” operation enables easy loading of the bale and excellent visibility of the wrapping process. The Autoswitch function enables the wrapper to fold from transport position into field position with a single push of a button on the ISOBUS terminal. The wrapper is 13’ in field position and folds to a narrow 8’ for transport.

Exceptional Bale Handling

The smart “drive through” design of the SW 4014 guarantees easy (un)loading of the bales, front- and backwards, even when dropped in hard-to-reach locations. All bales are (un)loaded without the risk of damaging or soil contamination because of the two patented* pair of steel rollers. To prevent film damage during transport, the SW 4014 is fitted with large wheel covers.

Easy Maintenance and Accessibility

The large side doors of the SW 4014 provide excellent accessibility for maintenance. Furthermore you can open the top cover and side doors without the need of tools. The SW 4014 can be equipped with an optional LED work light to have a better view on the wrapping process in the dark.

Non-Stop Wrapping With Autoload

The innovative AutoLoad function provides non-stop, fully automatic loading, wrapping and unloading of square- and round bales without interference from the driver. AutoLoad detects approaching bales, automatically scans the length of the bale and sets the loading arms into pre-load position, resulting in accurate loading, wrapping and unloading of the bale on the go. This leads to increased overall capacity and creates a more ergonomic and stress-free working environment during a long working day.

How Does It Work?

AutoLoad function is based on Category II Laser technology. First the laser sensor, situated inside the top cover at the front side of the machine, is scanning the area ahead of the bale wrapper. In addition, a wheel sensor is placed on the left wheel which measures the speed and distance toward the bale. Laser sensor is measuring ground level. Laser sensor has detected the bale. Laser sensor has detected the edge of the bale. Bale length measurement is starting by counting pulses on wheel sensor. Loading arms move to pre-load position (based on pre-defined bale width). Laser sensor has detected the end of the bale. The bale length is known. Depending on the driving speed, the loading arms are activated at the right time to load the bale in the center of the rollers. While wrapping, it is possible to drive already to the next bale. In case bales are dropped in ditches, under fences or even in corners of the field, the SW 4014 AutoLoad still allows you to load bales manually, forwards and backwards.

Twin-Satellite Design

The twin-satellite design ensures high-speed wrapping. The standard pre-stretchers, which each hold a 30” (750 mm) roll, are made of aluminum to avoid build-up of tack from the film. Both outer ends of the aluminum rollers are cone-shaped to maintain the optimum width of the film and reduce the risk of film tear. The special ribbed profile of the aluminum rollers keeps air and water away from the film. The location of the pre-stretchers makes it very easy to change the film rolls. The standard pre-stretch of 60% is reached by a low-maintenance and low-noise gear transmission. The positioning of the patented shorter top rollers allow the film roll holders to be positioned as low as possible. As a result, the film is wrapped closer to the center of the bale with less wrinkling, ensuring an optimum oxygen barrier for excellent silage quality. Once the desired number of film layers has been applied, the film is then held firmly and cut by two “scissor-type” film cutters. Due to this design, the film is caught across the full width. The film is held with a clamp, gathered into one solid rope and then cut before the bale is unloaded. The clamp firmly holds the film ready for the next bale.

IntelliWrap

Greater management and control of the wrapping process can be achieved by our unique IntelliWrap™. IntelliWrap uses sophisticated electronics and hydraulics to monitor the wrapping process and continuously controls the film overlap, allowing total flexibility. Depending on local circumstances, crop conditions and storage periods the amount of film layers (4, 5, 6, 7, 8, 9...) can simply be adjusted. An excellent distribution of the film around the bale and precise overlap of the film provides maximum efficiency and increased silage quality. 1. Selection of five film layers 2. The bale is covered with three layers and 67% overlap 3. Increasing of the bale rotational speed 4. Final two layers with 50% overlap