Kuhn RSM Series

Description

KUHN RSM roadside mowers provide the most efficient management of roadsides and ditches. The quality of work and adaptability are two main characteristics of these roadside mowers. They are suitable for tractors with 65 – 90 horsepower and are at ease in a wide variety of conditions. The models in the RSM range has been designed to meet local municipality needs for mowing work with greater safety over conventional rotary mowers.

Models

Oscillating Main Frame

An oscillating main frame, with floating pivot on the mowing head, allows the mowing head to adapt to the conditions and environment around it.Rear Roller

The 6” diameter rear roller provides optimal height control, eliminates ruts in loose soils and provides better clearance over irregular ground.Vertical Lift

The vertical lift automatically compensates for uneven ground. The models in the RSM range can mow on a higher plane than the road level. The vertical lift function also makes it easier to mow shallow ditches while maintaining an optimal drive position.Knife Options

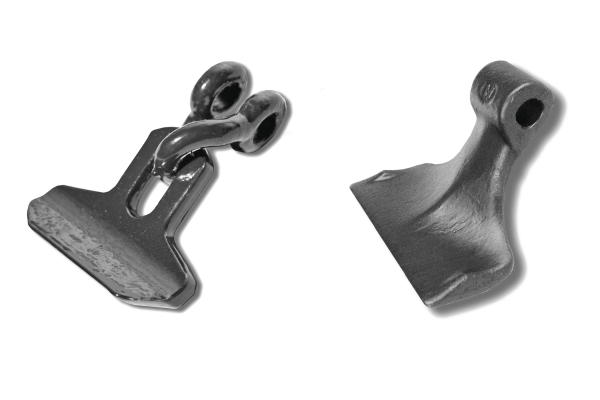

Articulated Hammer Knives Create lift for a clean cut. The shackle allows more freedom to clear obstructions hidden in grass conditions. Hammer Knives Hammer knives are designed for shredding with plenty of lift and extra weight to power through brush up to 2”. Not for use in rocky conditions.Heavy-Duty Belt Drive

The RSM utilizes a belt drive system built to handle heavy service. Its position keeps the PTO shaft as straight as possible, while the ventilated guard reduces heat buildup, extending the life of the belt.Mechanical Safety Breakaway System

A mechanical safety breakaway system protects the mower from inadvertent encounters with obstacles. Simply back the tractor up to reset and continue mowing.Structure of the Chassis and Frame

The structure of the chassis and frame are based on KUHN’s decades of experience with mowers and shredders. In the event of a collision with an obstacle, the mechanical safety device will protect the machine’s structure. Hydraulic non-stop protection is available as an option.Close Coupling

The specially designed headstock keeps the mower as close to the tractor as possible, offering outstanding controllability in both the mowing and transport positions.SPECIFICATIONS

| RSM 180 | RSM 210 | |

|---|---|---|

| Working width | 6' (1.83 m) | 7' (2.13 m) |

| Number of articulated hammer knives | 20 | 24 |

| Hydraulic control of inner and outer cutting head position | Standard | Standard |

| Inner protection cover | Standard | Standard |

| Mechanical breakaway system | Standard | Standard |

| Height adjustment by roller with removable ends | Standard | Standard |

| Curved skid shoes | Standard | Standard |

| Free wheel integrated in the central gearbox | Standard | Standard |

| Hitch type | 3-point, Cat. 2 (quick hitch compatible) | 3-point, Cat. 2 (quick hitch compatible) |

| Required tractor hydraulic connections | 2 SA - with float required | 2 SA - with float required |

| Machine net weight, approx. with roller | 1,565 lbs (710 kg) | 1,785 lbs (810 kg) |

| PTO speed (rpm) | 540 | 540 |

| Rotor drive | 4 - SPB belts | 4 - SPB belts |

| Minimum PTO power requirement | 65 hp (49 kW) | 65 hp (49 kW) |

| Maximum PTO power recommended | 90 hp (67 kW) | 90 hp (67 kW) |

Links

Copy Set

Oscillating Main Frame

An oscillating main frame, with floating pivot on the mowing head, allows the mowing head to adapt to the conditions and environment around it.

Rear Roller

The 6” diameter rear roller provides optimal height control, eliminates ruts in loose soils and provides better clearance over irregular ground.

Vertical Lift

The vertical lift automatically compensates for uneven ground. The models in the RSM range can mow on a higher plane than the road level. The vertical lift function also makes it easier to mow shallow ditches while maintaining an optimal drive position.

Knife Options

Articulated Hammer Knives Create lift for a clean cut. The shackle allows more freedom to clear obstructions hidden in grass conditions. Hammer Knives Hammer knives are designed for shredding with plenty of lift and extra weight to power through brush up to 2”. Not for use in rocky conditions.

Heavy-Duty Belt Drive

The RSM utilizes a belt drive system built to handle heavy service. Its position keeps the PTO shaft as straight as possible, while the ventilated guard reduces heat buildup, extending the life of the belt.

Mechanical Safety Breakaway System

A mechanical safety breakaway system protects the mower from inadvertent encounters with obstacles. Simply back the tractor up to reset and continue mowing.

Structure of the Chassis and Frame

The structure of the chassis and frame are based on KUHN’s decades of experience with mowers and shredders. In the event of a collision with an obstacle, the mechanical safety device will protect the machine’s structure. Hydraulic non-stop protection is available as an option.

Close Coupling

The specially designed headstock keeps the mower as close to the tractor as possible, offering outstanding controllability in both the mowing and transport positions.

SPECIFICATIONS

| RSM 180 | RSM 210 | |

|---|---|---|

| Working width | 6' (1.83 m) | 7' (2.13 m) |

| Number of articulated hammer knives | 20 | 24 |

| Hydraulic control of inner and outer cutting head position | Standard | Standard |

| Inner protection cover | Standard | Standard |

| Mechanical breakaway system | Standard | Standard |

| Height adjustment by roller with removable ends | Standard | Standard |

| Curved skid shoes | Standard | Standard |

| Free wheel integrated in the central gearbox | Standard | Standard |

| Hitch type | 3-point, Cat. 2 (quick hitch compatible) | 3-point, Cat. 2 (quick hitch compatible) |

| Required tractor hydraulic connections | 2 SA - with float required | 2 SA - with float required |

| Machine net weight, approx. with roller | 1,565 lbs (710 kg) | 1,785 lbs (810 kg) |

| PTO speed (rpm) | 540 | 540 |

| Rotor drive | 4 - SPB belts | 4 - SPB belts |

| Minimum PTO power requirement | 65 hp (49 kW) | 65 hp (49 kW) |

| Maximum PTO power recommended | 90 hp (67 kW) | 90 hp (67 kW) |