Kuhn VBP 3165 BalePack

| Make | Kuhn |

| Model | VBP 3165 BalePack |

| Type | Kuhn Round Balers |

Your Preferred Location

Description

Two technologies from KUHN are combined into one machine to create the VBP 3165 Variable BalePack. This baler-wrapper combination begins with a standard VB 3165 variable chamber baler with an OptiCut integral rotor and merges it with an innovative wrapper system. The VBP 3165 with ISOBUS steering and multiple in-cab controlled functions is designed to work in the heaviest conditions even on hilly ground.

Fast and reliable bale transfer, combined with a high-speed, twin-satellite wrapping unit equipped with IntelliWrap, gives the Kuhn VBP BalePack the capacity to reach an output of up to 60 bales per hour.

Fast and reliable bale transfer, combined with a high-speed, twin-satellite wrapping unit equipped with IntelliWrap, gives the Kuhn VBP BalePack the capacity to reach an output of up to 60 bales per hour.

Models

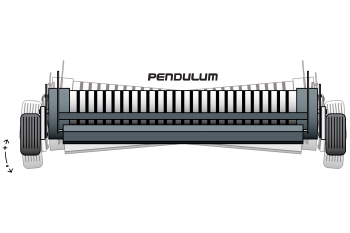

Optimal Crop Pickup

All VB 3100 models feature a wide pickup with standard crop roller. The pickup is designed to maximize the full capacity of the machine. With a working width of 91 inches, the machine is capable of working in all windrows and will not let you down, even in the toughest conditions. Straight pickup tines help release the crop and reduce crop wrapping. The pickup roller compresses the crop against the pickup tines reducing friction, thus reducing leaf loss and increasing baler efficiency by evening out the windrow. The 91” rotor model pickup features standard pendulum frame and optional pivoting pickup wheels to allow the pickup to adapt to changing field conditions. Camless-shaped crop guides, on 91” pickups, result in more aggressive and efficient pickup by exposing more of the tine when needed and by pulling the crop away from the tines as it approaches the intake. A cam track pulls the tines straight down in the rearward position to avoid wrapping, making this the only hybrid pickup on the market today.Integral Rotor Technology

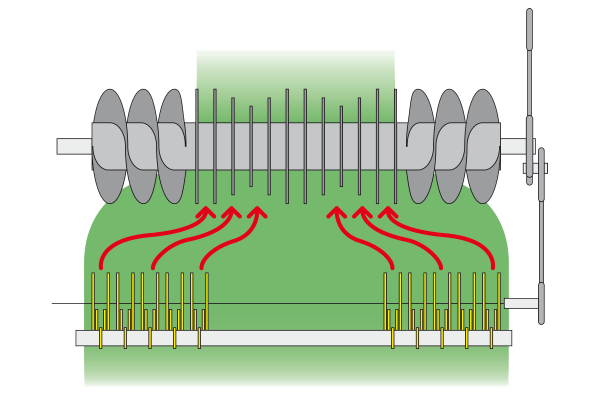

Patented Integral Rotor Technology found on the VBP 3165 baler-wrapper combination. This simple, low-maintenance intake system guarantees an enormous throughput capacity at all times. The short distance between rotor and pickup tines maintains consistent crop flow. The design of this force-fed intake makes higher forward speeds possible for increased productivity and reduces crop damage. The Integral Rotor on all models is provided with rotor tines made out of Hardox® wear plates. Hardox combines extreme hardness and toughness to reduce rotor tine wear. Longer wearing life of the rotor tines will help to provide time and money savings for the operator.Cutting, OptiCut Rotors

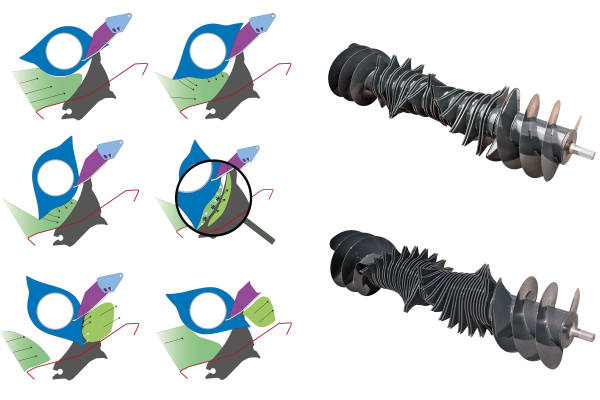

The OptiCut (OC) cutting rotors are designed for unlimited intake capacity and excellent cutting quality. KUHN (OC) cutting rotors, with elliptical shaped rotor tines, are acknowledged by users as one of the best cutting systems on the market. The silage is guided and drawn down to the knives from an early stage which improves flow and cutting performance and also prevents unwanted plugging. The VBP 3165 can be equipped with the OptiCut 14 or OptiCut 23 rotor to best suit your needs. The Integral Rotor, with the 14-knife OptiCut system, is designed to even out the windrow and force-feed the crop into the baler for maximum throughput. The 14-knife OptiCut cutting system provides a theoretical cutting length of 2 ¾". Each single knife is spring protected against damage from foreign objects. With group selection (VB 3165 & 3195 models) the operator can choose to have 0, 4, 7, 7, or 14 knives in operation. The Integral Rotor with the 23-knife OptiCut system from KUHN has the benefits of intensive cutting and mechanical protection. The 23-knife OptiCut system provides a theoretical cutting length of 1 ¾". Each single knife is spring protected against damage from foreign objects. With group selection the operator can choose to have 0, 7, 11, 12, or 23 knives in operation.Progressive Density – The KUHN Solution

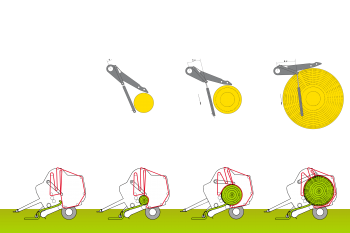

The Progressive Density system has proven its value on all KUHN VB balers. The system increases tension as the bale grows providing a firm bale with a tough outer shell. How Does It Work? As the bale grows within the bale chamber, the belt tensioning arm is subjected to steadily increasing resistance from two hydraulic cylinders and a spring tensioner. So as the diameter increases, the bale’s density does too. The result is a very firm bale with a moderate core – not too soft, not too hard. With a tougher outer layer, straw bales will be more tolerant to bad weather conditions, while silage bales will maintain their shape for improved stacking and easier handling.Fast, Perfect Bale Formation

The 5 belt, 3 roller design of the VB 3100 Series bale chamber ensures fast, consistent bale formation whatever the intake system. The aggressive profile of the top chamber roller improves crop contact and reduces crop loss. The front segment of the baler is fitted with a large smooth roller and driven cleaning roller that prevents crop build up at the front of the machine. The unique mix of the KUHN Progressive Density system and smart bale chamber design guarantees perfect bale formation every time.Net and Twine

One of the final steps in creating the perfect bale is the wrap. Securing a bale to protect it from the elements and from losing its shape is one of the most crucial steps. The less time required to secure the bale, the higher the baling operation output.Rapid and Secure Bale Transfer

To minimize idle time and maximize output, a rapid bale transfer is required. The side guide protection plates of the KUHN VB BalePack ensure a rapid and secure bale transfer even when working in steep or sloping fields. The 4-belt wrapping table with 2 large rollers and 4 side cones provide maximum bale traction, bale rotation and proper film overlap, regardless of the bale shape.Patented, Simple Pre-Stretcher

The pre-stretcher holds two 30" rolls of film and maintains a 70% stretch evenly throughout the roll. Conical ends maintain optimum film width and reduce tearing. Aluminum construction avoids buildup of tack from the film. The design and location makes it very easy to change film rolls compared to competitive models.IntelliWrap, The Intelligent Wrapping Technology

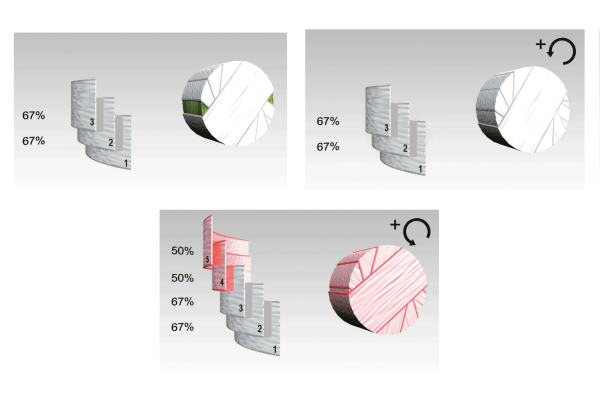

KUHN has been a pioneer in wrapping and baling technology. The latest result of this visionary approach is a revolutionary wrapping technique called IntelliWrap. This technology uses computer-controlled electronics and hydraulics to monitor the wrapping process and continuously control the film overlap, allowing complete flexibility. For the best conservation and fermentation of your valuable crop, wrapping the bale is crucial in this process. Depending on personal preferences, crop conditions and the storage period 5 layers of film may be enough, while in other circumstances 7 layers of film are preferred. Using IntelliWrap adjustments are simple—from your tractor seat you can easily adjust the number of film layers on the monitor. Just select 4,5,6,7,8 (no other wrapper manufacturers offer selection of 5 or 7 layers) or more layers of film and confirm. When selecting 5 layers, a minimum of 5 layers of film are applied to each and every portion of the bale.3D Wrapping

KUHN’s 3D wrapping distributes the total film quantity more uniformly and efficiently across the entire surface of the bale. 3D wrapping will first apply the film where it is most needed, the corners of the bale. After finishing the complete 3D wrapping cycle, approximately 80% of the bale is already covered in film. Then the conventional wrapping will make sure that 100% of the bale is covered with stretch film. The film has a perfect oxygen barrier because all layers are glued together with tack. The cylindrical wrap ensures that the bale retains its shape, even after long storage periods. Use of both IntelliWrap and 3D wrapping provides well-shaped, tightly sealed bales and will maintain silage quality over long storage periods.Specifications

- Automatic stop by end of film / tear: Standard

- Axle type: Standard tandem

- Bale chamber: 1 starter roller - 2 bale chamber rollers - 5 belts

- Bale chamber idler rollers: Standard with heavy-duty bearings and seals

- Bale diameter: 31.5" to 63" (80 cm to 160 cm)

- Bale packaging system: Choice of net wrap or twine and net wrap system

- Bale pressure: 20 - 235 bar (monitor controlled)

- Bale size - width x diameter: 4' X 5' (1.2 m X 1.5 m)

- Bale support: 4 rollers

- Bale width: 47" (119 cm)

- Belts: Standard endless belts

- Brake system: Standard hydraulic

- Chain lubrication system: Standard Beka-Max continuous chain oiler system

- Electronic monitor: Choice of VT 50, CCI 1200, or no monitor

- Film roll magazine: Holds up to 10 rolls of stretch film

- Intake system: Standard 14 or 23 knife OptiCut with integral rotor and drop floor system

- Knife protection system: Spring

- Minimum machine weight: 12,550 lbs (5,693 kg)

- Net storage: Standard up to 2 rolls

- Number of knives: 14 with group selection the operator can choose to have 0, 4, 7, 7, or 14 knives in operation or 23 with group selection the operator can choose to have 0, 7, 11, 12, or 23 knives in operation

- Number of pickup tine bars: 5

- Oil flow and pressure required: 10.5 GPM at 2,650 PSI

- Pickup gauge wheels: Choice of fixed or pivoting wheels

- Pickup width: 91" (231 cm)

- Pickup wind guard: Standard large crop roller

- Pre-stretch ratio: Standard 70% - optional 60% pre-stretcher kit

- PTO power requirement: OC 14 110 / 130 OC 23 125 / 145

- PTO speed: Standard 540

- PTO type: Standard CV PTO (1 3/8" - 6 splines) with cam clutch

- Required tractor hydraulic connections: 1 DA and 1 SA with a 3/4" free return

- Tires: Choice of 400/60-22.5 or 500/45-22.5 tires

- Transport width: 9'10" (3 m)

- Wrapping system: Twin satellite

- Wrapping table: 2 rollers and 4 belts

Links

Copy Set

Optimal Crop Pickup

All VB 3100 models feature a wide pickup with standard crop roller. The pickup is designed to maximize the full capacity of the machine. With a working width of 91 inches, the machine is capable of working in all windrows and will not let you down, even in the toughest conditions. Straight pickup tines help release the crop and reduce crop wrapping. The pickup roller compresses the crop against the pickup tines reducing friction, thus reducing leaf loss and increasing baler efficiency by evening out the windrow. The 91” rotor model pickup features standard pendulum frame and optional pivoting pickup wheels to allow the pickup to adapt to changing field conditions. Camless-shaped crop guides, on 91” pickups, result in more aggressive and efficient pickup by exposing more of the tine when needed and by pulling the crop away from the tines as it approaches the intake. A cam track pulls the tines straight down in the rearward position to avoid wrapping, making this the only hybrid pickup on the market today.

Integral Rotor Technology

Patented Integral Rotor Technology found on the VBP 3165 baler-wrapper combination. This simple, low-maintenance intake system guarantees an enormous throughput capacity at all times. The short distance between rotor and pickup tines maintains consistent crop flow. The design of this force-fed intake makes higher forward speeds possible for increased productivity and reduces crop damage. The Integral Rotor on all models is provided with rotor tines made out of Hardox® wear plates. Hardox combines extreme hardness and toughness to reduce rotor tine wear. Longer wearing life of the rotor tines will help to provide time and money savings for the operator.

Cutting, OptiCut Rotors

The OptiCut (OC) cutting rotors are designed for unlimited intake capacity and excellent cutting quality. KUHN (OC) cutting rotors, with elliptical shaped rotor tines, are acknowledged by users as one of the best cutting systems on the market. The silage is guided and drawn down to the knives from an early stage which improves flow and cutting performance and also prevents unwanted plugging. The VBP 3165 can be equipped with the OptiCut 14 or OptiCut 23 rotor to best suit your needs. The Integral Rotor, with the 14-knife OptiCut system, is designed to even out the windrow and force-feed the crop into the baler for maximum throughput. The 14-knife OptiCut cutting system provides a theoretical cutting length of 2 ¾". Each single knife is spring protected against damage from foreign objects. With group selection (VB 3165 & 3195 models) the operator can choose to have 0, 4, 7, 7, or 14 knives in operation. The Integral Rotor with the 23-knife OptiCut system from KUHN has the benefits of intensive cutting and mechanical protection. The 23-knife OptiCut system provides a theoretical cutting length of 1 ¾". Each single knife is spring protected against damage from foreign objects. With group selection the operator can choose to have 0, 7, 11, 12, or 23 knives in operation.

Progressive Density – The KUHN Solution

The Progressive Density system has proven its value on all KUHN VB balers. The system increases tension as the bale grows providing a firm bale with a tough outer shell. How Does It Work? As the bale grows within the bale chamber, the belt tensioning arm is subjected to steadily increasing resistance from two hydraulic cylinders and a spring tensioner. So as the diameter increases, the bale’s density does too. The result is a very firm bale with a moderate core – not too soft, not too hard. With a tougher outer layer, straw bales will be more tolerant to bad weather conditions, while silage bales will maintain their shape for improved stacking and easier handling.

Fast, Perfect Bale Formation

The 5 belt, 3 roller design of the VB 3100 Series bale chamber ensures fast, consistent bale formation whatever the intake system. The aggressive profile of the top chamber roller improves crop contact and reduces crop loss. The front segment of the baler is fitted with a large smooth roller and driven cleaning roller that prevents crop build up at the front of the machine. The unique mix of the KUHN Progressive Density system and smart bale chamber design guarantees perfect bale formation every time.

Net and Twine

One of the final steps in creating the perfect bale is the wrap. Securing a bale to protect it from the elements and from losing its shape is one of the most crucial steps. The less time required to secure the bale, the higher the baling operation output.

Rapid and Secure Bale Transfer

To minimize idle time and maximize output, a rapid bale transfer is required. The side guide protection plates of the KUHN VB BalePack ensure a rapid and secure bale transfer even when working in steep or sloping fields. The 4-belt wrapping table with 2 large rollers and 4 side cones provide maximum bale traction, bale rotation and proper film overlap, regardless of the bale shape.

Patented, Simple Pre-Stretcher

The pre-stretcher holds two 30" rolls of film and maintains a 70% stretch evenly throughout the roll. Conical ends maintain optimum film width and reduce tearing. Aluminum construction avoids buildup of tack from the film. The design and location makes it very easy to change film rolls compared to competitive models.

IntelliWrap, The Intelligent Wrapping Technology

KUHN has been a pioneer in wrapping and baling technology. The latest result of this visionary approach is a revolutionary wrapping technique called IntelliWrap. This technology uses computer-controlled electronics and hydraulics to monitor the wrapping process and continuously control the film overlap, allowing complete flexibility. For the best conservation and fermentation of your valuable crop, wrapping the bale is crucial in this process. Depending on personal preferences, crop conditions and the storage period 5 layers of film may be enough, while in other circumstances 7 layers of film are preferred. Using IntelliWrap adjustments are simple—from your tractor seat you can easily adjust the number of film layers on the monitor. Just select 4,5,6,7,8 (no other wrapper manufacturers offer selection of 5 or 7 layers) or more layers of film and confirm. When selecting 5 layers, a minimum of 5 layers of film are applied to each and every portion of the bale.

3D Wrapping

KUHN’s 3D wrapping distributes the total film quantity more uniformly and efficiently across the entire surface of the bale. 3D wrapping will first apply the film where it is most needed, the corners of the bale. After finishing the complete 3D wrapping cycle, approximately 80% of the bale is already covered in film. Then the conventional wrapping will make sure that 100% of the bale is covered with stretch film. The film has a perfect oxygen barrier because all layers are glued together with tack. The cylindrical wrap ensures that the bale retains its shape, even after long storage periods. Use of both IntelliWrap and 3D wrapping provides well-shaped, tightly sealed bales and will maintain silage quality over long storage periods.