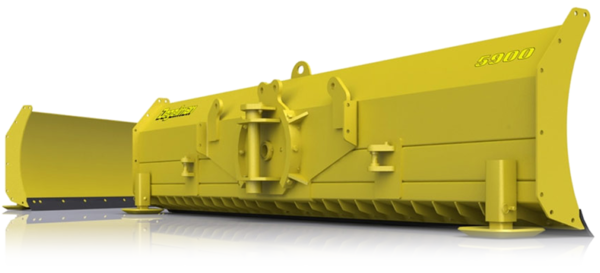

Degelman 5900

Models

125-500 HP 5900 Series

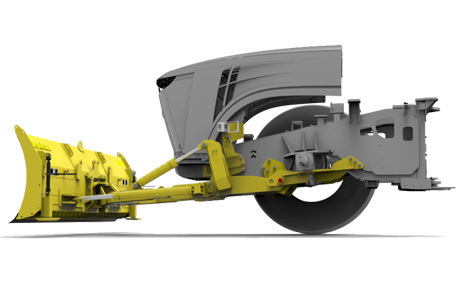

The 5900 Series has all the features such as tilt, higher profile, D-lock® mid-mounting, and industrial skid shoes.Side Bracket / Front Hook Mount

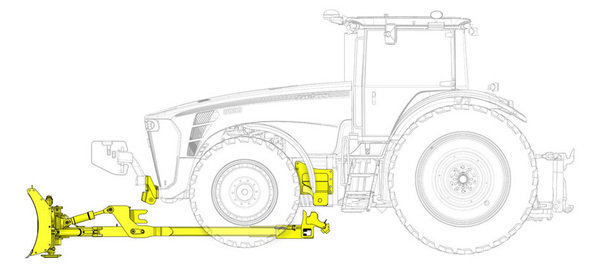

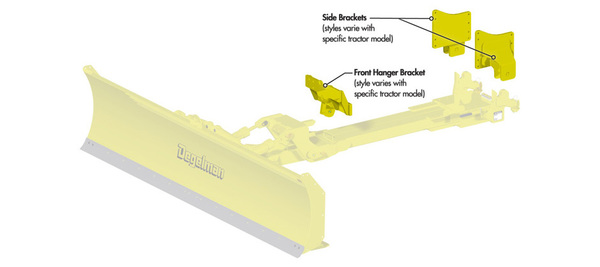

5900 Blades commonly mount using a front mounted hook and two side brackets. The operator typically drives into the front hook, connects the hydraulics, hydraulically lifts the rear frame into position, and secures the "D-Lock" connections on the rear axle brackets. (46/5700 shown in illustration)5900

Common Components

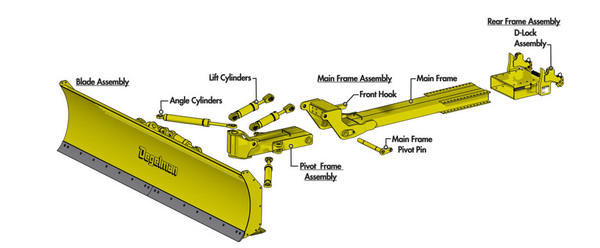

Many of the 5900 blade assemblies use common components in different configurations. Here are some basic descriptions of some common components.5900

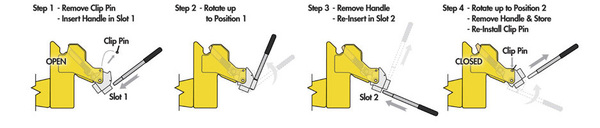

ONE PERSON, NO TOOLSQuick-Attach D-Lock® Mounting

The D-Lock® mounting system offers the convenience of quick attach/detach as well as long life. No tools are required. Fit-ups are 100% secure with zero movement. The blade can be removed in minutes by disengaging two points on the front axle brackets.Range of Motion

6-Way: Hydraulic Lift, Angle & Tilt5900

*Not available for 4600 or 6600 model.No Welding - Easy Bolt-On Assembly

Simple, Bolt-on brackets are all that is attached to your tractor. The rest of the assembly quickly attaches and detaches from these simple brackets. The brackets can also be removed if needed!5900

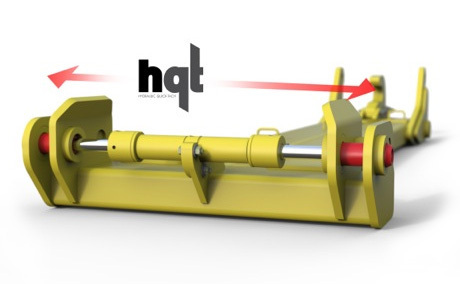

In the spirit of safety and simplicity, Degelman has pushed the design process one more time by coming up with the all new HQT-Hydraulic Quick Tach System. This precision built feature utilizes a hydraulic pin engagement concept which allows the operator to secure the blade to the Dozer mounting framework from the tractor seat. It avoids the dangers, awkwardness and hassles of crawling around the tractor to secure the dozer engagement. Just one more example of how Degelman pushes design to make things a little safer, more convenient and last longer.SPECIFICATIONS - 2WD & MFWA

| Dozer Series |

5900 |

| Tractor Horsepower Range |

125 - 500 hp |

| Tractor Type |

2WD & FWA |

| Blade Widths |

10', 12', 14' |

| Blade Weight |

3,390 - 3,660 lbs |

| Blade Height (standard) |

36" |

| Blade Height (with top extension) |

43" |

| Blade Height (with silage extension) |

60" |

| Lifting Height (approx) |

23" |

| Lift Cylinders |

3-1/2" dia |

| Hydraulic Angle |

24° |

| Hydraulics - Angle |

3" x 20" |

| Hydraulic - Vertical Tilt |

15° |

| Tilt Cylinders |

3" x 8" |

| Cutting Edge (MaxTemp® Steel) |

5/8" x 6" |

| Digging Depth |

10" - 14" |

| Skid Shoes (abrasion resistant) |

Standard Adjustment |

| Mounting System |

D-lock® Quick-Tach / HQT |

| Mounting Location |

Rear Axle / Mid-Mount |

| Mouldboard (ripple formed blade) |

3/16" |

One Robust Blade

If you're running a modern two-wheel drive or a front-wheel-assisted tractor, we've got an industrial-strength blade made just for you. The 5900 comes out of the gate with 0° to 24° all-angle capabilities, 9° tilt and 28" hydraulic lift. In addition, the 5900 has higher profile, D-lock® mid-mounting and industrial-strength AR400 skid shoes. Add to that, all the features that are Degelman standards-such as double-skin blade construction, Monarch manufactured cylinders and the toughest testing around-and you've got one robust blade.Features

- Degelman Industries has been engineering tough, high performance equipment for almost 60 years. The result is outstanding equipment that exceeds expectations and outperforms. We achieve this through meticulous design and vigilant customer service.: No two tractor manufacturers are alike, so we don’t develop a blade that is “one size fits all. Degelman engineers, designs and individually builds all Bulldozer Tractor fit-ups to ensure proper mounting locations are the best spot to push from - protecting your tractor investment. Featuring a Precision Machined Tubing Finish, Superior Seals and High Grade Wear Bands the Degelman series of Bulldozer Blades adds value and versatility to your tractor.

- FIND THE BLADE SERIES THAT'S RIGHT FOR YOU 40-150 HP 3500 Series 65-380 HP 4600/5700 Series 125-500 HP 5900 Series 200-500 HP 66/69/7200 Series 300-700 HP 7900 Hi-Lift Series: Designed to mount on popular utility tractors, this blade is a smaller version of the 4600 and 5700 Series. The 4600 and 5700 Series hydraulic angle blade attaches to both front-wheel assist and two-wheel drive tractors. The 5900 Series has all the features such as tilt, higher profile, D-lock® mid-mounting, and industrial skid shoes. Compatible with today’s high horse-power 4-wheel drive tractors, this series handles the most challenging jobs on your farm. 6600-Manual Angle 6900-Hydraulic Angle 7200-Hydraulic Angle & Hydraulic Tilt Developed specifically for producers moving silage and haylage, the 7900 can also take on the toughest snow removal jobs. With a lifting capacity of 40", a blade height of 47" tall, and an increased angle of 30° to eliminate spillover, the 7900 is backed with over 40 years of blade experience.

- Top Extension Silage Extension High Volume Side Plate One-Foot Extension Bite Extension Rubber Cutting Edge Urethane Cutting Edge Max Temp® Steel: Top extension attachments are designed to maximize pushing capacity by preventing spillover. Our Degelman Silage Extensions are made from heavy-grade steel and are two feet high so you have maximum volume control. They’re also see-through for increased safety and efficiency. Whatever degree your blade is angled at, adding a High Volume Side Plate means you can dramatically improve the amount of volume you can push. It also decreases the amount of snow trailing off your blade so you move more snow with fewer passes. If you want a bigger blade, or if you add dual wheels to your tractor and want extensions as wide as your wheelbase, our One-Foot Extensions are the answer. Easy to add and as strong as the blade they’re attached to. Similar to our One-Foot Extension, our Bite Extension allows you to doze along curbs, foundations or silage container bunks and scrape material off without leaving a trail. Designed to be used either for slurry barns or for snow removal. The Rubber Cutting Edge essentially squeegees barn floors easily for maximum material pick-up. And for snow removal usage, the rubber edge means you can doze without fear of tripping on manhole covers. A harder material made for close scraping and removal of compact snow and ice. The Urethane Cutting Edge is a durable polymer that gives you three times the wear resistance of rubber while protecting you from tripping on manhole covers. Available for Strongbox only. MaxTemp steel is the same steel that’s used in industrial bulldozer blades. It’s made from hardened high carbon steel that’s strong and durable without being brittle. Made for dozing dirt, levelling roadways, gravel or snow.

- Quick-Attach D-Lock® Mounting: The D-Lock® mounting system offers the convenience of quick attach/detach as well as long life. No tools are required. Fit-ups are 100% secure with zero movement. The blade can be removed in minutes by disengaging two points on the front axle brackets.

Copy Set

125-500 HP 5900 Series

Side Bracket / Front Hook Mount

5900

Common Components

5900

Quick-Attach D-Lock® Mounting

Range of Motion

5900

No Welding - Easy Bolt-On Assembly

5900

SPECIFICATIONS - 2WD & MFWA

| Dozer Series |

5900 |

| Tractor Horsepower Range |

125 - 500 hp |

| Tractor Type |

2WD & FWA |

| Blade Widths |

10', 12', 14' |

| Blade Weight |

3,390 - 3,660 lbs |

| Blade Height (standard) |

36" |

| Blade Height (with top extension) |

43" |

| Blade Height (with silage extension) |

60" |

| Lifting Height (approx) |

23" |

| Lift Cylinders |

3-1/2" dia |

| Hydraulic Angle |

24° |

| Hydraulics - Angle |

3" x 20" |

| Hydraulic - Vertical Tilt |

15° |

| Tilt Cylinders |

3" x 8" |

| Cutting Edge (MaxTemp® Steel) |

5/8" x 6" |

| Digging Depth |

10" - 14" |

| Skid Shoes (abrasion resistant) |

Standard Adjustment |

| Mounting System |

D-lock® Quick-Tach / HQT |

| Mounting Location |

Rear Axle / Mid-Mount |

| Mouldboard (ripple formed blade) |

3/16" |