John Deere 2635 Three- and Five-Section Tandem Disks

Description

- Perfect for heavy soils, residue sizing/incorporation

- Features John Deere TruSet™ Tillage Technology

- Radial Tire Option

- Knife-edge Rolling Basket

- Extended-Life Bearing

Models

Mechanical wing control increases frame levelness for five-section disks

Spring pack

Spring pack

Spring pack

Spring pack

John Deere’s mechanical wing control helps producers keep their frames level for five-section disks. Mechanical wing control is included in base equipment for all five-section 2630 Series Disks.

With this feature, a large spring is placed in the wing frame on each side of the disk. As the pivot point in the wing starts to raise, the spring presses against that point to keep the disk level through tough field conditions.

The red circles below illustrate the area of the disk where the large spring is placed in the wing frame.

Mechanical wing control

Mechanical wing control

John Deere’s mechanical wing control is an industry-exclusive feature. A five-section disk without mechanical wing control can show up to 75-mm (3-in.) of depth inconsistency across the wing frame.

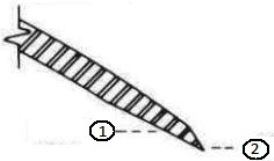

230-mm (9-in.) and 280-mm (11-in.) blade spacing available for 2635 Disk

The 2635 General-Purpose Disk comes equipped with front and rear solid-spherical disk blades with 280-mm (11-in.) spacing. The primary blade size is 610 mm (24 in.) x 6.5 mm (0.256 in.).

Additional blade options for the 2635 are listed below.

230-mm (9-in.) disk spacing

230-mm (9-in.) disk spacing

280-mm (11-in.) disk spacing

280-mm (11-in.) disk spacing

280-mm (11-in.) spacing, front and rear

- Excels in high residue conditions where residue flow may cause plugging on narrower spacing

- Allows for more weight to be transferred per blade which increases penetration in heavy soils

230-mm (9-in.) front spacing/280-mm (11-in.) rear spacing

- Works well in primary tillage in all soil types

- Provides excellent residue sizing capability with 230-mm (9-in.) spacing on the front gang

- Allows for increased residue handling capabilities with 280-mm (11-in.) rear gang spacing

NOTE:

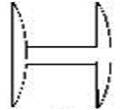

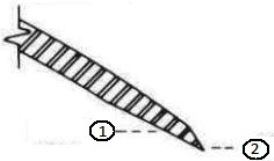

- The number 1 edge has a beefier profile and is best for rocky conditions.

- The number 10 edge has a narrower profile and should work well in most non-rock conditions.

- Rear main and wing gangs are tapered with one blade 51 mm (2 in.) smaller than the primary blade.

- Integral furrow filler blades are included with all rear wing gangs which are 102 mm (4 in.) smaller than the primary blade.

- Front outer gangs have a taper that is 51 mm (2 in.) smaller than the primary blade, except for 560-mm (22-in.) disk blades.

Number 1 edge (outside bevel, outside grind)

Number 1 edge (outside bevel, outside grind)

Number 10 edge (inside bevel, outside grind)

Number 10 edge (inside bevel, outside grind)

- Bevel

- Grind

2630 Series includes disks for light, medium, and heavy-duty tillage

Ground-engaging components on 2633

Ground-engaging components on 2633

Ground-engaging components on 2633

Ground-engaging components on 2633

The John Deere 2630 Series offer three disk models that provide a wide range of variety for all tillage applications.

Model |

2630 Disk | 2633 Disk | 2635 Disk |

| Purpose | Secondary (light duty) | Dual purpose (medium duty) | Primary (heavy duty) |

| Working depth | Up to 130 mm (5 in.) | Up to 180 mm (7 in.) | Up to 200 mm (8 in.) |

| Weight per blade | Minimum 68 kg (150 lb) | Under 13.4 m (44 ft) Minimum 86 kg (190 lb) Over 13.4 m (44 ft) Minimum 91 kg (200 lb) |

Minimum 127 kg (280 lb) |

| Blade size | 560 or 610 mm (22 in. or 24 in.) |

610 or 660 mm (24 in. or 26 in.) |

610 or 660 mm (24 in. or 26 in.) |

| Blade spacing | 185 or 230 mm (7.25 in. or 9 in.) |

230 mm (9 in.) | 230 mm (9 in.) (front) and 280 mm (11 in.) (rear), or 280 mm (11 in.) |

| Horsepower | 23 - 36 hp/m (7 - 11 hp/ft) | 23 - 36 hp/m (7 - 11 hp/ft) | 26 - 36 hp/m (8 - 11 hp/ft) |

| Working widths | 6.3 m - 15.0 m (20.75 ft - 49.25 ft) |

6.3 m - 15.0 m (20.75 ft - 49.25 ft) |

7.2 m-12.4 m (23.58 - 40.66 ft) |

| Operating speed | 6.5 - 11.3 km/h (4 - 7 mph) |

6.5 - 11.3 km/h (4 - 7 mph) |

6.5 - 11.3 km/h (4 - 7 mph) |

| Recommended use |

|

|

|

Multiple enhancements made to 2630 Series Disks

The 2630 Series Disks offer multiple upgrades and new items as options versus the 2620 Series Disks to enhance the machine. Check out the following video sharing more about the new 2630 Series Disks.

Extended-life bearings

John Deere’s 2630 Series Disks and Vertical Tillage Implements feature extended-life bearings. These more durable and reliable bearings allow producers to customize bearing maintenance for specific growing conditions and soil type.

TruSet™ side-to-side feature

John Deere TruSet system is featured in base equipment for the 2630 Series Disks and Vertical Tillage Implements. TruSet side-to-side is also available and features individual section leveling.

Knife-edge hydraulic rolling basket

The hydraulic rolling basket is now offered with a round bar, flat bar, or knife-edge. The knife-edge is best for heavier, wet soil, and can be used in rocky conditions.

Radial tires

The 2630 Series Disks and Vertical Tillage Implements feature radial tires for the mainframes in base equipment. Radial tires are available as an option on the wing frame and stabilizer wheels. These tires are designed to offer longer wear life and help minimize compaction with a wider plate and lower inflation pressures.

Stabilizer wheels

Producers can choose either mechanical stabilizer wheels or TruSet hydraulic stabilizer wheels as an option. Stabilizer wheels help to maintain a consistent, level depth and are recommended for operation on rolling ground. The mechanical stabilizer wheels can be manually adjusted with a turnbuckle. TruSet with side-to-side leveling capabilities also enables operators to control the TruSet hydraulic stabilizer wheels from the cab while on the go.

Variety of residue managing solutions available

As crop yields increase, so does the amount of residue after harvest. The John Deere 2623 and 2625 Disks provide operators with a disk that can be set to prepare a seedbed for planting or set to bury and size tough residue in primary tillage applications.

Utilize the residue calculator to identity the optimal residue management solution to meet the producer’s needs.

Extended-life bearings improve productivity

John Deere’s 2630 Series Disks and Vertical Tillage Implements feature extended-life bearings. These more durable and reliable bearings allow producers to customize bearing maintenance for specific growing conditions and soil types.

The flange-mounted bearing and sealing system features improved contamination resistance. The advanced seal material is highly resistant to wear and damage caused by abrasive soils and other crop materials. The design of these are more durable and reliable than previous bearings.

The design of this bearing system allows for dynamic self-alignment to the gang bolt, as opposed to trunnion-mounted bearings that have limited alignment capability. This system features additional freedom of movement, accommodating a wider variety of field conditions. The bearing system has been designed to decrease stress and fatigue on the inner rolling surfaces, supporting extended bearing life.

The bearing and seal design allows for a limited, seasonal maintenance interval to minimize downtime. They also allow producers to customize the maintenance for specific growing conditions and soil types. The multi-lipped sealing system cannot be damaged by frequent greasing. It allows bearings to accept grease within the bearing as well as provide grease to the outer bearing surface to eliminate wear between the bearing and housing. With this design, the bearings can accept grease even if misaligned to the housing.

Easily tension disk gang bolts

51-mm (2-in.) disk gang bolts

51-mm (2-in.) disk gang bolts

Gang tension system

Gang tension system

John Deere's 2630 Series Disks provide an innovative approach to tension disk gang bolts.

Hydraulic fore-aft leveling enables operators to level disks from tractor cab

Hydraulic fore-aft leveling

Hydraulic fore-aft leveling

Hydraulic fore-aft leveling comes as standard equipment with John Deere's 2630 Series Disks. Operators can level the disk from the comfort of the tractor cab.

Different blade options for soil penetration and residue sizing

John Deere's 2630 Series Disks offer different blade options for soil penetration and residue sizing.

Solid-spherical blade

Solid-spherical blade

Cutout-spherical blade

Cutout-spherical blade

| Blade type | Solid-spherical blades | Cutout-spherical blades |

| Recommended application |

|

|

| Recommended soil type | Light to medium soils | Heavy to medium soils |

| Benefits | Better control of soil than cone blades since less sensitive to over speeding | Chopping or trapping residue |

| Penetration | Penetrate best at a 20-degree gang angle | Penetration is excellent with a cutout blade |

Disk blade options

- Disk blades compatible with 2630 Disk

- Disk blades compatible with 2633 Disk

- Disk blades compatible with 2635 Disk

Features

- Working Speed: 5 to 7 mph (8-11.3 km/h)

- Required HP (Engine)/FT: 9 to 12 (22.05-29.4 kw/m)

- Weight /blade: 280 lbs to 286 lbs (127-129.7 kg)

- Residue Conditions: medium/heavy

- Working Depth: up to 8 in (203 mm)

- Depth Control: TruSet/Single-point

Copy Set

Mechanical wing control increases frame levelness for five-section disks

Spring pack

Spring pack

Spring pack

Spring pack

John Deere’s mechanical wing control helps producers keep their frames level for five-section disks. Mechanical wing control is included in base equipment for all five-section 2630 Series Disks.

With this feature, a large spring is placed in the wing frame on each side of the disk. As the pivot point in the wing starts to raise, the spring presses against that point to keep the disk level through tough field conditions.

The red circles below illustrate the area of the disk where the large spring is placed in the wing frame.

Mechanical wing control

Mechanical wing control

John Deere’s mechanical wing control is an industry-exclusive feature. A five-section disk without mechanical wing control can show up to 75-mm (3-in.) of depth inconsistency across the wing frame.

230-mm (9-in.) and 280-mm (11-in.) blade spacing available for 2635 Disk

The 2635 General-Purpose Disk comes equipped with front and rear solid-spherical disk blades with 280-mm (11-in.) spacing. The primary blade size is 610 mm (24 in.) x 6.5 mm (0.256 in.).

Additional blade options for the 2635 are listed below.

230-mm (9-in.) disk spacing

230-mm (9-in.) disk spacing

280-mm (11-in.) disk spacing

280-mm (11-in.) disk spacing

280-mm (11-in.) spacing, front and rear

- Excels in high residue conditions where residue flow may cause plugging on narrower spacing

- Allows for more weight to be transferred per blade which increases penetration in heavy soils

230-mm (9-in.) front spacing/280-mm (11-in.) rear spacing

- Works well in primary tillage in all soil types

- Provides excellent residue sizing capability with 230-mm (9-in.) spacing on the front gang

- Allows for increased residue handling capabilities with 280-mm (11-in.) rear gang spacing

NOTE:

- The number 1 edge has a beefier profile and is best for rocky conditions.

- The number 10 edge has a narrower profile and should work well in most non-rock conditions.

- Rear main and wing gangs are tapered with one blade 51 mm (2 in.) smaller than the primary blade.

- Integral furrow filler blades are included with all rear wing gangs which are 102 mm (4 in.) smaller than the primary blade.

- Front outer gangs have a taper that is 51 mm (2 in.) smaller than the primary blade, except for 560-mm (22-in.) disk blades.

Number 1 edge (outside bevel, outside grind)

Number 1 edge (outside bevel, outside grind)

Number 10 edge (inside bevel, outside grind)

Number 10 edge (inside bevel, outside grind)

- Bevel

- Grind

2630 Series includes disks for light, medium, and heavy-duty tillage

Ground-engaging components on 2633

Ground-engaging components on 2633

Ground-engaging components on 2633

Ground-engaging components on 2633

The John Deere 2630 Series offer three disk models that provide a wide range of variety for all tillage applications.

Model |

2630 Disk | 2633 Disk | 2635 Disk |

| Purpose | Secondary (light duty) | Dual purpose (medium duty) | Primary (heavy duty) |

| Working depth | Up to 130 mm (5 in.) | Up to 180 mm (7 in.) | Up to 200 mm (8 in.) |

| Weight per blade | Minimum 68 kg (150 lb) | Under 13.4 m (44 ft) Minimum 86 kg (190 lb) Over 13.4 m (44 ft) Minimum 91 kg (200 lb) |

Minimum 127 kg (280 lb) |

| Blade size | 560 or 610 mm (22 in. or 24 in.) |

610 or 660 mm (24 in. or 26 in.) |

610 or 660 mm (24 in. or 26 in.) |

| Blade spacing | 185 or 230 mm (7.25 in. or 9 in.) |

230 mm (9 in.) | 230 mm (9 in.) (front) and 280 mm (11 in.) (rear), or 280 mm (11 in.) |

| Horsepower | 23 - 36 hp/m (7 - 11 hp/ft) | 23 - 36 hp/m (7 - 11 hp/ft) | 26 - 36 hp/m (8 - 11 hp/ft) |

| Working widths | 6.3 m - 15.0 m (20.75 ft - 49.25 ft) |

6.3 m - 15.0 m (20.75 ft - 49.25 ft) |

7.2 m-12.4 m (23.58 - 40.66 ft) |

| Operating speed | 6.5 - 11.3 km/h (4 - 7 mph) |

6.5 - 11.3 km/h (4 - 7 mph) |

6.5 - 11.3 km/h (4 - 7 mph) |

| Recommended use |

|

|

|

Multiple enhancements made to 2630 Series Disks

The 2630 Series Disks offer multiple upgrades and new items as options versus the 2620 Series Disks to enhance the machine. Check out the following video sharing more about the new 2630 Series Disks.

Extended-life bearings

John Deere’s 2630 Series Disks and Vertical Tillage Implements feature extended-life bearings. These more durable and reliable bearings allow producers to customize bearing maintenance for specific growing conditions and soil type.

TruSet™ side-to-side feature

John Deere TruSet system is featured in base equipment for the 2630 Series Disks and Vertical Tillage Implements. TruSet side-to-side is also available and features individual section leveling.

Knife-edge hydraulic rolling basket

The hydraulic rolling basket is now offered with a round bar, flat bar, or knife-edge. The knife-edge is best for heavier, wet soil, and can be used in rocky conditions.

Radial tires

The 2630 Series Disks and Vertical Tillage Implements feature radial tires for the mainframes in base equipment. Radial tires are available as an option on the wing frame and stabilizer wheels. These tires are designed to offer longer wear life and help minimize compaction with a wider plate and lower inflation pressures.

Stabilizer wheels

Producers can choose either mechanical stabilizer wheels or TruSet hydraulic stabilizer wheels as an option. Stabilizer wheels help to maintain a consistent, level depth and are recommended for operation on rolling ground. The mechanical stabilizer wheels can be manually adjusted with a turnbuckle. TruSet with side-to-side leveling capabilities also enables operators to control the TruSet hydraulic stabilizer wheels from the cab while on the go.

Variety of residue managing solutions available

As crop yields increase, so does the amount of residue after harvest. The John Deere 2623 and 2625 Disks provide operators with a disk that can be set to prepare a seedbed for planting or set to bury and size tough residue in primary tillage applications.

Utilize the residue calculator to identity the optimal residue management solution to meet the producer’s needs.

Extended-life bearings improve productivity

John Deere’s 2630 Series Disks and Vertical Tillage Implements feature extended-life bearings. These more durable and reliable bearings allow producers to customize bearing maintenance for specific growing conditions and soil types.

The flange-mounted bearing and sealing system features improved contamination resistance. The advanced seal material is highly resistant to wear and damage caused by abrasive soils and other crop materials. The design of these are more durable and reliable than previous bearings.

The design of this bearing system allows for dynamic self-alignment to the gang bolt, as opposed to trunnion-mounted bearings that have limited alignment capability. This system features additional freedom of movement, accommodating a wider variety of field conditions. The bearing system has been designed to decrease stress and fatigue on the inner rolling surfaces, supporting extended bearing life.

The bearing and seal design allows for a limited, seasonal maintenance interval to minimize downtime. They also allow producers to customize the maintenance for specific growing conditions and soil types. The multi-lipped sealing system cannot be damaged by frequent greasing. It allows bearings to accept grease within the bearing as well as provide grease to the outer bearing surface to eliminate wear between the bearing and housing. With this design, the bearings can accept grease even if misaligned to the housing.

Easily tension disk gang bolts

51-mm (2-in.) disk gang bolts

51-mm (2-in.) disk gang bolts

Gang tension system

Gang tension system

John Deere's 2630 Series Disks provide an innovative approach to tension disk gang bolts.

Hydraulic fore-aft leveling enables operators to level disks from tractor cab

Hydraulic fore-aft leveling

Hydraulic fore-aft leveling

Hydraulic fore-aft leveling comes as standard equipment with John Deere's 2630 Series Disks. Operators can level the disk from the comfort of the tractor cab.

Different blade options for soil penetration and residue sizing

John Deere's 2630 Series Disks offer different blade options for soil penetration and residue sizing.

Solid-spherical blade

Solid-spherical blade

Cutout-spherical blade

Cutout-spherical blade

| Blade type | Solid-spherical blades | Cutout-spherical blades |

| Recommended application |

|

|

| Recommended soil type | Light to medium soils | Heavy to medium soils |

| Benefits | Better control of soil than cone blades since less sensitive to over speeding | Chopping or trapping residue |

| Penetration | Penetrate best at a 20-degree gang angle | Penetration is excellent with a cutout blade |