John Deere VT17 Series Vertical Tillage Tools

Disks

Your Preferred Location

Features

-

PTO HP: 70 - 90 hp (51.5 - 66.2 kW)

-

Working Width: 10 ft. 6 in. (3.2 m)

-

Hitch: Drawn/Clevis

Simple adjustments for increased uptime

Three adjustments to properly set up the VT17 Series Vertical Tillage Tool

Adjust depth of tillage tool

Adjust depth of tillage tool

Depth: adjust the depth of the tool with a simple pin and clip system. Choose between 0-76 mm (0-3 in.).

NOTE: Make sure to adjust back to transport mode when moving the unit from field to field.

Use crank to level the tillage tool

Use crank to level the tillage tool

Fore/aft leveling: turn the crank’s handle at the front of the machine to level the front and rear of the tillage tool. Turning the crank clockwise will lower the rear and turning counterclockwise will raise the rear. To prevent ridging, Frontier™ equipment recommends readjusting the levelness when the unit is at actual working depth.

Adjust gang angles to change aggressiveness

Adjust gang angles to change aggressiveness

Gang angle: use the included angle adjusting lever to shift the slide plate to the desired setting. The gang angles adjust from 0-12 degrees. A larger angle will cause a more aggressive cut in the soil.

Furrow fillers for VT17 Series Vertical Tillage Tool

Optional furrow filler

Optional furrow filler

Furrow fillers on the outside of the rear gangs reduce outside ridges and smooth out the soil surface.

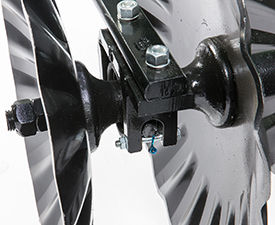

Maintenance-free bearings increase the life of moving parts, increasing uptime

Greaseable bearing shown

Greaseable bearing shown

Choose between sealed or greaseable bearings. Sealed bearings do not require regular maintenance, and reduce the chance for contamination, lengthening the life of the bearing. Greaseable bearings typically have a longer life, but require routine maintenance.

Scraper kits for VT17 Series Vertical Tillage Tool

Optional scrapers for shallow concave blade

Optional scrapers for shallow concave blade

Scraper kits for the VT17 Series disk blades and furrow fillers help remove buildup in wet, sticky soil types.

NOTE: Scraper kits are only needed if choosing the shallow, concave blade option.

Working widths that allow for easy road transport and increased asset utilization

VT1710 shown with 3-m (10.5-ft) working width

VT1710 shown with 3-m (10.5-ft) working width

Growers can choose between four working widths: 3 m, 3.7 m, 4 m, and 4.6 m (10.5 ft, 12 ft, 13 ft, and 15 ft). Vertical tillage units are known for their high horsepower requirements, causing some producers to purchase larger tractors to accommodate. The VT17 Series working widths allow the horsepower requirements to remain low, which lets growers use their current utility tractors to practice vertical tillage. These widths also allow for easy road transport in most areas.

Adjustable gang angles for desired aggressiveness

Adjust gang angles to change aggressiveness

Adjust gang angles to change aggressiveness

The gang angles on the VT17 Series adjust from 0 to 12 degrees. For growers practicing true vertical tillage, gang angles should be set at 0 degrees. However, the VT17 Series also has the capability for a more aggressive cut to satisfy growers with harder soil types. To adjust the gang angle, use the included angle adjusting lever to shift the slide plate to a desired setting.

An option exists for growers to order a reduced gang angle, limiting the adjustment to 0 to 5 degrees. With this option, growers meet minimum tillage requirements for many state-run, governmental conservation programs.

Middle breaker kit for VT17 Series Vertical Tillage Tool

Optional middle breaker

Optional middle breaker

An optional, adjustable middle breaker mounts between the wheels on the center frame tube. It acts as a soil disrupter in the centerline of travel left open where the front and rear gangs do not overlap.

Rolling baskets and blade options enable a smooth field finish

Two blade options for the VT17 Series Vertical Tillage Tool

Straight fluted blade

Straight fluted blade

Shallow concave fluted blade

Shallow concave fluted blade

- Straight fluted blades

- 50.8-cm (20-in.) diameter

- 6-mm (0.24-in.) thickness

- Less aggressive cut

- Shallow concave fluted blades

- 55.9-cm (22-in.) diameter

- 5-mm (0.20-in.) thickness

- More aggressive cut

Each blade is fluted, allowing the soil to mix and the crop to incorporate into the soil. True vertical tillage is achieved with straight blades at a 0-degree gang angle. However, depending on soil conditions, crop residue, and the grower’s desired field finish, a higher-degree gang angle or shallow concave blades may be needed.

35.6-cm (14-in.) diameter rolling basket

Rolling basket finishing attachment

Rolling basket finishing attachment

Down pressure adjustment

Down pressure adjustment

- Designed to break up clods for improved levelness and uniformity of field finish

- Down-pressure adjustment: in changing field conditions, use the double-nut adjustment on the rolling basket to produce desired field finish