John Deere 2430C Nutrient Applicator

| Make | John Deere |

| Model | 2430C |

| Type | Application Toolbars |

Your Preferred Location

Description

- 19- and 25-row configurations

- Redesigned 25-row model with improved transport dimensions

- TruSet™ Tillage technology

- Coulters and closing disks now optional

Models

Improved transport dimensions

Beginning with model year 2022, the 2430C Nutrient Applicator includes everything producers enjoyed about the previous 2430C, but with improved transport dimensions.

Lower transport height of 25-row 2430C

Lower transport height of 25-row 2430C

2430C Nutrient Applicator

2430C Nutrient Applicator

- The 25-row, 19-m (62.5-ft) 2430C is available with a 4.3-m (14-ft) transport height (0.76 m [2.5 ft] lower than the previous model).

- The updated 5.5-m (18-ft, 2-in.) transport width is 1.1 m (3.6-ft) narrower than the previous 25-row model.

- The placement of the outer wings allows maximum working widths and low transport height under bridges and utility lines.

Preparing to fold the 2430C for transportt

Preparing to fold the 2430C for transportt

Folding the 2430C for transport

Folding the 2430C for transport

Folding the 2430C for transport

Folding the 2430C for transport

2430C fully folded for transport

2430C fully folded for transport

Learn more about the redesigned transport dimensions here.

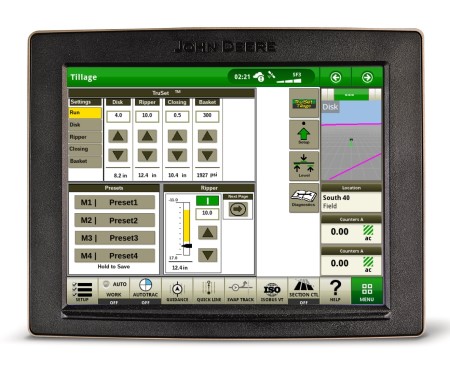

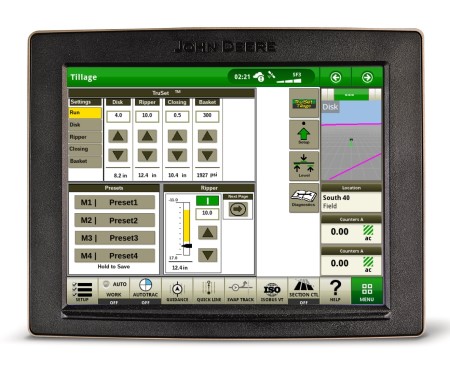

TruSet™ Tillage technology

Integrated TruSet Tillage technology enables operators to respond to changing field conditions such as varying soils, heavier residue, and moisture by adjusting depth while on the go.

With a short window of time to perform tillage operations, TruSet can provide significant productivity improvements as operators can adjust the nutrient applicator with the push of a button while covering acres. By responding to conditions as they change throughout the field, TruSet enables operators to generate a better-quality tillage performance with the first pass.

Using a Gen 4 display, an operator sees real-time data for depth control, providing assurance of desired tillage outcomes. Once the actual set point is validated and configured to the display in the cab, operators can make independent adjustments as small as 2.5 mm (0.1 in.). Four customizable presets enable operators to save and name different combinations of settings for their most common field conditions.

TruSet on the in-cab display

TruSet on the in-cab display

TruSet Side-to-Side

2430C operators have the option to enhance the TruSet Tillage system with individual section leveling functionality.

Functionality by control option

| Single-point | TruSet | TruSet Side-to-Side | |

| One adjustment to change implement depth | X | X | X |

| Mechanical adjustment option | X | X | X |

| In-cab adjustment option | --- | X | X |

| In-cab individual section leveling | --- | --- | X |

| Tillage documentation and prescription | --- | X | X |

Document nutrient depth with TruSet Tillage

With integrated TruSet Tillage technology, operators can document nutrient application depth. The tillage documentation feature allows producers to capture and analyze the pass for additional coverage of the crop production cycle.

Single-point depth control

Single-point depth control

Single-point depth control

Single-point depth control is included on all 2430C models. Hydraulic routings on the 2430C are designed to allow each implement to feature both TruSet and standard single-point depth control for system redundancy, operator preference, and flexibility at resale.

The depth stop and valve are mounted directly to the frame and cylinder pins for precise, repeatable depth settings. Single-point depth control:

- Provides 6 mm (0.25 in.) of operating depth change per turn

- Simple up-front location depth adjustment for the entire machine

- Cylinder eyebolt adjustment for frame leveling

- Valve assembly attached to the frame and front castering wheel assembly for consistent and repeatable valve activation

- Valve assembly attached to the frame and cylinder pins to promote consistent and repeatable valve activation

Proven frame design

19-row 3.4-m (134-in.) four-rank frame

19-row 3.4-m (134-in.) four-rank frame

25-row 3.4-m (134-in.) four-rank frame

25-row 3.4-m (134-in.) four-rank frame

25-row 3.4-m (134-in.) four-rank frame

25-row 3.4-m (134-in.) four-rank frame

The four-rank frame design of the 2430C has provided unmatched reliability to John Deere operators for over 10 years and a countless amount of acres. The thick frame tubes, diagonal bracing, and frame gussets on the 2430C can endure tractors with 447.4 engine kW (600 engine hp).

The frame stretches 3.4 m (11.15 ft) front-to-back, which allows for high levels of residue to easily flow through the staggered row units ensuring higher productivity and consistent nutrient placement. The large frame member sizes, tube-through-tube construction, and wheel module placement adds to the structural integrity, providing a stable front-to-rear and side-to-side operation.

The ease of accessibility to the maintenance points of the machine is achieved through 1.1 m (44 in.) of underframe clearance. This enables the operator to save valuable time while experiencing less fatigue for routine maintenance and service.

Frame construction offers:

-

Consistent operating depth

-

Improved nutrient placement

-

Clear view of machine operation

- 10 degrees up flex and 15 degrees down flex

Tru-Depth heavy-duty cast standards

The Tru-Depth heavy-duty cast standards on the 2430C Nutrient Applicators are designed for precise and accurate nutrient placement and offer 567 kg (1250 lb) of trip force to allow for faster operating speeds. The conventional standard supports the anhydrous knife on both sides, greatly reducing shear bolt failure when encountering field obstacles.

Conventional heavy-duty Tru-Depth standard

Conventional heavy-duty Tru-Depth standard

Heavy-duty cast standards

Heavy-duty cast standards

Adjustable closing disks

Adjustable closing disks operating in worked ground

Adjustable closing disks operating in worked ground

As the nutrient knife places anhydrous, closing disks bring soil back for proper sealing. Soil types, moisture, and residue levels can greatly affect the amount and consistency of the soil that is brought back in. The closing disks on the 2430C can be adjusted from a narrow setting of 220 mm (8.8 in.) apart to the widest setting of 430 mm (17 in.) apart for industry leading adjustability.

The closing disk system on the 2430C requires no tools for adjustability. Fore-aft and lateral settings are pin adjustable and have variable down force. This makes for quick, easy adjustments that allow for customizable settings to meet field finish preferences. For increased productivity and ease of serviceability, there are no grease zerks on the closing disks assembly.

The 460-mm (18-in.) concave notched blades close the slot and seal the anhydrous in the soil. The closing disks are designed with down-pressure springs built in, which limits bounce in rough field conditions. The closing arms have been engineered to flex as large obstructions (clods, rocks, etc.) flow between the knife and the blade. Independent up and down travel arms are key to the nearly plug-free closing disk. This allows one machine to operate in any soil type and eliminates the need to have multiple disk sealer attachments along with labor required to change them out.

Pin-adjust closing disk

Pin-adjust closing disk

Rear hitch

The 2430C is equipped with a rear hitch capable of towing up to 11,364 kg (25,000 lb).

Tank hookup is made easier by extending the drawbar outwards and side-to-side laterally. It is constructed of heavy-duty tubing to ensure reliability and withstands higher towing capacity demands.

19-row and 25-row sizes available

2430C Nutrient Applicator

2430C Nutrient Applicator

The 2430C Nutrient Applicator is available in two machine configurations:

- 19 row – 3.66-m (12-ft) center frame, five-section, 305-mm (30-in.) spacing

- 25 row – 3.66-m (12-ft) center frame, five-section, 305-mm (30-in.) spacing

Size |

Working width |

Transport width |

Transport height |

19 row |

14.5 m (47 ft, 6 in.) |

6.0 m (19 ft, 8 in.) |

4.30 m (14 ft, 1 in.) |

25 row |

19.1 m (62 ft, 6 in.) |

5.5 m (18 ft, 2 in.) |

4.3 m (14 ft) |

The five individual frame sections can be adjusted independently of each other. The operator can tailor the depth setting of individual sections to ensure proper product sealing and fertilizer placement even in compressed wheel track areas and varying field conditions.

Specifications

- Clearance - Fore-and-aft clearance: 3.4 m<br/>134 in.

- Clearance - Underframe clearance: Fully raised: 1100 mm<br/>44 in.

- Closing Disks - Blade type: Concave notched

- Closing Disks - Disk blade diameter: 460 x 3 mm<br/>18 x 0.118 in.

- Closing Disks - Max down pressure: 222 N<br/>50 lbf

- Closing Disks - Mounting: Independently mounted arms with pin adjustment

- Closing Disks - Side to side adjustment range: 220 to 460 mm<br/>8.8 to 17 in.

- Closing Disks - Trip height: 465 mm<br/>19.5 in.

- Coulters - Blade diameter: 560 x 4.5 mm<br/>22 x 0.177 in.

- Coulters - Blade spacing: 762 mm<br/>30 in.

- Coulters - Coulter down force: 2669 N<br/>600 lbf

- Dimensions - Centerframe width: 19 row: 3.66 m<br/>12 ft<br/>25 row: 4.57 m<br/>15 ft

- Dimensions - Overall length: 9.75 m<br/>32 ft

- Dimensions - Transport height: 19 row: 4.3 m (14 ft, 1 in.)<br/>25 row: 4.3 m (14 ft, 1 in.)

- Dimensions - Transport width: 19 row: 6 m (19 ft, 8 in.)<br/>25 row: 5.5 m (18 ft, 2 in.)

- Dimensions - Working widths: 19 row: 14.5 m<br/>47.5 ft<br/>Row 25: 19.1 m<br/>62.5 ft

- Hitch and Frame - Depth control system: TruSet depth control system or single-point depth control system

- Hitch and Frame - Frame flex: 10 degrees up / 15 degrees down

- Hitch and Frame - Hitch link: Category 4 or 5

- Hitch and Frame - Hitch system: Pull type: Floating hitch<br/>rigid T-hitch - 6 x 12 in.<br/>152 x 305 mm

- Hitch and Frame - Rear hitch: Fore/aft and side-to-side adjustable drawbar

- Hitch and Frame - Rear hitch maximum gross vehicle weight (GVW): 11,300 kg<br/>25,000 lb

- Key Specs - Centerframe width: 19 row: 3.66 m<br/>12 ft<br/>25 row: 4.57 m<br/>15 ft

- Key Specs - Fold type: Five-section fold

- Key Specs - Machine weight - chisel: 19 row: 10,003 kg<br/>22,052 lb<br/>25 row: 11,060 kg<br/>24,384 lb

- Key Specs - Machine weight - conventional: 19 row: 11,939 kg<br/>26,320 lb<br/>25 row: 13,608 kg<br/>30,000 lb

- Key Specs - Number of rows: 19, 25

- Key Specs - Overall length: 9.75 m<br/>32 ft

- Key Specs - Row spacing: 762 mm<br/>30 in.

- Key Specs - Transport height: 19 row: 4.3 m (14 ft, 1 in.)<br/>25 row: 4.3 m (14 ft, 1 in.)

- Key Specs - Transport width: 19 row: 6 m (19 ft, 8 in.)<br/>25 row: 5.5 m (18 ft, 2 in.)

- Key Specs - Working widths: 19 row: 14.5 m<br/>47.5 ft<br/>Row 25: 19.1 m<br/>62.5 ft

- Machine configuration - Fold type: Five-section fold

- Machine configuration - Number of rows: 19, 25

- Machine configuration - Row spacing: 762 mm<br/>30 in.

- Standards - Number of standards: 19, 25

- Standards - Standard Operating depth range: 76 to 305 mm<br/>3 to 12 in.

- Standards - Standard options: Conventional knife options with coulters and closing disks<br/>Conventional or mole knife<br/>Tru-Depth™ conventional

- Standards - Standard spacing: 762 mm<br/>30 in.

- Standards - Standard trip force: 5560 N<br/>1250 lbf

- Standards - Standard trip height: 280 mm<br/>11 in.

- Tires and wheels - Tire configuration: 19 row: Mainframe tires: 320/70R15 145D (six)<br/>Inner wing tires: 320/70R15 145D (two) 280/70R15 134D (four)<br/>Outer wing tires: 280/70R15 134D (six)<br/>25 row: Mainframe tires: 320/70R15 145D (six)<br/>Inner wing tires: 320/70R15 145D (six)<br/>Outer wing tires: 500/40R16 153A8/B (two)

- Tires and wheels - Wheel mounting: Castering front with walk-over tandem rear

- Tractor compatibility - Engine horsepower requirement: 19 row: 268.5 to 387.8 kW<br/>360 to 520 hp<br/>25 row: 372.8 to 462.3 kW<br/>500 to 620 hp

- Tractor compatibility - Operating speed: 8 to 16 km/h<br/>5 to 10 mph

- Tractor compatibility - Selective control valves (SCVs) required: Two

- Weight - Machine weight: conventional<br/>19 row: 11,939 kg<br/>26,320 lb<br/>25 row: 13,608 kg<br/>30,000 lb<br/>chisel<br/>19 row: 10,003 kg<br/>22,052 lb<br/>25 row: 11,060 kg<br/>24,384 lb<br/>

Features

- Number of Rows: 19, 25

-

Season: Pre-plant

Post-harvest -

Engine hp Needed: 18-27.5 hp/row 19-row

20-24.8 hp/row 25-row

Copy Set

Improved transport dimensions

Beginning with model year 2022, the 2430C Nutrient Applicator includes everything producers enjoyed about the previous 2430C, but with improved transport dimensions.

Lower transport height of 25-row 2430C

Lower transport height of 25-row 2430C

2430C Nutrient Applicator

2430C Nutrient Applicator

- The 25-row, 19-m (62.5-ft) 2430C is available with a 4.3-m (14-ft) transport height (0.76 m [2.5 ft] lower than the previous model).

- The updated 5.5-m (18-ft, 2-in.) transport width is 1.1 m (3.6-ft) narrower than the previous 25-row model.

- The placement of the outer wings allows maximum working widths and low transport height under bridges and utility lines.

Preparing to fold the 2430C for transportt

Preparing to fold the 2430C for transportt

Folding the 2430C for transport

Folding the 2430C for transport

Folding the 2430C for transport

Folding the 2430C for transport

2430C fully folded for transport

2430C fully folded for transport

Learn more about the redesigned transport dimensions here.

TruSet™ Tillage technology

Integrated TruSet Tillage technology enables operators to respond to changing field conditions such as varying soils, heavier residue, and moisture by adjusting depth while on the go.

With a short window of time to perform tillage operations, TruSet can provide significant productivity improvements as operators can adjust the nutrient applicator with the push of a button while covering acres. By responding to conditions as they change throughout the field, TruSet enables operators to generate a better-quality tillage performance with the first pass.

Using a Gen 4 display, an operator sees real-time data for depth control, providing assurance of desired tillage outcomes. Once the actual set point is validated and configured to the display in the cab, operators can make independent adjustments as small as 2.5 mm (0.1 in.). Four customizable presets enable operators to save and name different combinations of settings for their most common field conditions.

TruSet on the in-cab display

TruSet on the in-cab display

TruSet Side-to-Side

2430C operators have the option to enhance the TruSet Tillage system with individual section leveling functionality.

Functionality by control option

| Single-point | TruSet | TruSet Side-to-Side | |

| One adjustment to change implement depth | X | X | X |

| Mechanical adjustment option | X | X | X |

| In-cab adjustment option | --- | X | X |

| In-cab individual section leveling | --- | --- | X |

| Tillage documentation and prescription | --- | X | X |

Document nutrient depth with TruSet Tillage

With integrated TruSet Tillage technology, operators can document nutrient application depth. The tillage documentation feature allows producers to capture and analyze the pass for additional coverage of the crop production cycle.

Single-point depth control

Single-point depth control

Single-point depth control

Single-point depth control is included on all 2430C models. Hydraulic routings on the 2430C are designed to allow each implement to feature both TruSet and standard single-point depth control for system redundancy, operator preference, and flexibility at resale.

The depth stop and valve are mounted directly to the frame and cylinder pins for precise, repeatable depth settings. Single-point depth control:

- Provides 6 mm (0.25 in.) of operating depth change per turn

- Simple up-front location depth adjustment for the entire machine

- Cylinder eyebolt adjustment for frame leveling

- Valve assembly attached to the frame and front castering wheel assembly for consistent and repeatable valve activation

- Valve assembly attached to the frame and cylinder pins to promote consistent and repeatable valve activation

Proven frame design

19-row 3.4-m (134-in.) four-rank frame

19-row 3.4-m (134-in.) four-rank frame

25-row 3.4-m (134-in.) four-rank frame

25-row 3.4-m (134-in.) four-rank frame

25-row 3.4-m (134-in.) four-rank frame

25-row 3.4-m (134-in.) four-rank frame

The four-rank frame design of the 2430C has provided unmatched reliability to John Deere operators for over 10 years and a countless amount of acres. The thick frame tubes, diagonal bracing, and frame gussets on the 2430C can endure tractors with 447.4 engine kW (600 engine hp).

The frame stretches 3.4 m (11.15 ft) front-to-back, which allows for high levels of residue to easily flow through the staggered row units ensuring higher productivity and consistent nutrient placement. The large frame member sizes, tube-through-tube construction, and wheel module placement adds to the structural integrity, providing a stable front-to-rear and side-to-side operation.

The ease of accessibility to the maintenance points of the machine is achieved through 1.1 m (44 in.) of underframe clearance. This enables the operator to save valuable time while experiencing less fatigue for routine maintenance and service.

Frame construction offers:

-

Consistent operating depth

-

Improved nutrient placement

-

Clear view of machine operation

- 10 degrees up flex and 15 degrees down flex

Tru-Depth heavy-duty cast standards

The Tru-Depth heavy-duty cast standards on the 2430C Nutrient Applicators are designed for precise and accurate nutrient placement and offer 567 kg (1250 lb) of trip force to allow for faster operating speeds. The conventional standard supports the anhydrous knife on both sides, greatly reducing shear bolt failure when encountering field obstacles.

Conventional heavy-duty Tru-Depth standard

Conventional heavy-duty Tru-Depth standard

Heavy-duty cast standards

Heavy-duty cast standards

Adjustable closing disks

Adjustable closing disks operating in worked ground

Adjustable closing disks operating in worked ground

As the nutrient knife places anhydrous, closing disks bring soil back for proper sealing. Soil types, moisture, and residue levels can greatly affect the amount and consistency of the soil that is brought back in. The closing disks on the 2430C can be adjusted from a narrow setting of 220 mm (8.8 in.) apart to the widest setting of 430 mm (17 in.) apart for industry leading adjustability.

The closing disk system on the 2430C requires no tools for adjustability. Fore-aft and lateral settings are pin adjustable and have variable down force. This makes for quick, easy adjustments that allow for customizable settings to meet field finish preferences. For increased productivity and ease of serviceability, there are no grease zerks on the closing disks assembly.

The 460-mm (18-in.) concave notched blades close the slot and seal the anhydrous in the soil. The closing disks are designed with down-pressure springs built in, which limits bounce in rough field conditions. The closing arms have been engineered to flex as large obstructions (clods, rocks, etc.) flow between the knife and the blade. Independent up and down travel arms are key to the nearly plug-free closing disk. This allows one machine to operate in any soil type and eliminates the need to have multiple disk sealer attachments along with labor required to change them out.

Pin-adjust closing disk

Pin-adjust closing disk

Rear hitch

The 2430C is equipped with a rear hitch capable of towing up to 11,364 kg (25,000 lb).

Tank hookup is made easier by extending the drawbar outwards and side-to-side laterally. It is constructed of heavy-duty tubing to ensure reliability and withstands higher towing capacity demands.

19-row and 25-row sizes available

2430C Nutrient Applicator

2430C Nutrient Applicator

The 2430C Nutrient Applicator is available in two machine configurations:

- 19 row – 3.66-m (12-ft) center frame, five-section, 305-mm (30-in.) spacing

- 25 row – 3.66-m (12-ft) center frame, five-section, 305-mm (30-in.) spacing

Size |

Working width |

Transport width |

Transport height |

19 row |

14.5 m (47 ft, 6 in.) |

6.0 m (19 ft, 8 in.) |

4.30 m (14 ft, 1 in.) |

25 row |

19.1 m (62 ft, 6 in.) |

5.5 m (18 ft, 2 in.) |

4.3 m (14 ft) |

The five individual frame sections can be adjusted independently of each other. The operator can tailor the depth setting of individual sections to ensure proper product sealing and fertilizer placement even in compressed wheel track areas and varying field conditions.