John Deere 5045E Utility Tractor

5 Series Utility Tractors

Your Preferred Location

Features

-

PTO HP: 37 (27.6)

-

Hitch Category: Category 2<br /> (convertible to 1)

-

Economy PTO: No

-

Engine HP: 50 (37.4)

-

2WD or 4WD: Both

-

Cab or Open Station: Open Station

Specifications

Capacities - Fuel tank: |

Standard: 72.5 L 19 U.S. gal. |

Dimensions - Approximate shipping weight, Open;Cab: |

MFWD: 2525 kg 5566 lb |

Dimensions - Overall length: |

3639 mm 143.3 in. |

Dimensions - Wheelbase: |

2WD and MFWD: 2050 mm 80.7 in. |

Electrical system - Type of bulb in beacon (Halogen, Zenon, LED): |

|

Electrical system - Type of bulb in headlight (Halogen, Zenon, LED): |

|

Engine performance - Maximum PTO power: |

@ 1800 RPM: Open Station - 28.5kw (38hp) |

Engine performance - Rated power: |

At 2100 rpm: 37.4 kW 50 hp |

Engine performance - Rated PTO power (hp SAE): |

At 2100 rpm: 27.6 kW (37 PTO) |

Engine specifications - Aspiration: |

Turbocharged |

Engine specifications - Cylinders liners: |

Wet sleeved |

Engine specifications - Description: |

John Deere PowerTech 3029 |

Engine specifications - Displacement: |

3 cylinders: 2.9 L 179 cu in. |

Hydraulic system - Available flow at a single rear SCV: |

43.4 L/min 11.5 gpm |

Hydraulic system - Joystick SCV control: |

2WD: FIK MFWD: Standard |

Hydraulic system - Number of mid selective control valves (SCVs): |

Standard: 0 Optional: 2 |

Hydraulic system - Number of rear selective control valves (SCVs): |

standard: 1 Optional: 2 |

Hydraulic system - Pump rated output: |

Standard: 66.1 L/min 17.5 gpm |

Hydraulic system - Type: |

Open Center |

Key Specs - Engine description: |

John Deere PowerTech 3029 |

Key Specs - Engine displacement: |

3 cylinders: 2.9 L 179 cu in. |

Key Specs - Hydraulic pump rated output: |

Standard: 66.1 L/min 17.5 gpm |

Key Specs - Maximum PTO power: |

@ 1800 RPM Open Station: 28.5kw (38hp) |

Key Specs - Rated engine power: |

At 2100 rpm: 37.4 kW 50 hp |

Key Specs - Rated PTO power (hp SAE): |

At 2100 rpm: 27.6 kW (37 PTO) |

Key Specs - Rear hitch category (SAE designation): |

Category 2; convertible to 1 |

Key Specs - Transmission type: |

Standard: 9F/3R SyncShuttle |

Miscellaneous - Country of manufacture: |

Sub assembly in Pune, India, Final assembly in Augusta, GA |

Operator station - Rollover protective structure, OOS: |

Rigid - foldable - telescopic Foldable, 2-post Platform - flat/straddle Straddle Gearshift location - console/floor Floor, on the side |

Operator station - Seat: |

Mechanical |

Rear axle - Axle type: |

Flanged |

Rear axle - Brakes, type and control: |

Hydraulic wet disc |

Rear axle - Differential controls: |

Mechanical (pedal) |

Rear axle - Final drive type: |

Planetary |

Rear hitch - Hitch category (SAE designation): |

Category 2; convertible to 1 |

Rear hitch - Hitch draft control load sense type: |

Mechanical |

Rear hitch - Maximum lift capacity behind lift points: |

OECD hitch lift cap at 24 behind: 3192 lb 1448 kg |

Rear hitch - Remote control valves available: |

Standard: 1 Optional: 2 |

Rear hitch - Sensing type: |

Top link |

Rear power take-off (PTO) - Engine rpm (at rated PTO speeds): |

540 at 2100 rpm |

Rear power take-off (PTO) - PTO actuation: |

Mechanical (lever) |

Rear power take-off (PTO) - Type: |

Standard: Independent 540 |

Tires - Front: |

2WD: 7.5-16 R1 MFWD: 9.5-24 R1 |

Tires - Rear: |

2WD: 13.6-28 R1 MFWD: 13.6-28 R1 |

Tires - Turning radius with brakes: |

2WD: 3.1 m 10.2 ft MFWD: 3.94 m 12.9 ft |

Tires - Turning radius without brakes: |

2WD: 3.5 m 11.5 ft MFWD: 4.65 m 15.3 ft |

Transmission - Clutch; wet/dry: |

Dry |

Transmission - Reverser: |

No |

Transmission - Type: |

Standard: 9F/3R SyncShuttle |

Weight - Base machine weight: |

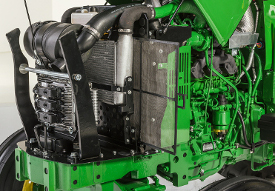

Final Tier 4-compliant PowerTech™ engines provide improved visibility

A smaller, more efficient after-treatment device provides more space under the hood

A smaller, more efficient after-treatment device provides more space under the hood

The 5045E, 5055E, 5065E, and 5075E Utility Tractors meet U.S. Environmental Protection Agency (EPA) Final Tier 4 (FT4) exhaust emissions regulations with a diesel oxidation catalyst (DOC)/diesel particulate filter (DPF) system. Modifying the after-treatment device resulted in better forward and side visibility around the hood. The hood slope of the updated design is comparable to the Tier 2 tractors previously produced. Similar to the system on the 5M, the purpose of the DOC/DPF combination is to reduce toxic gases emitted from the exhaust, as well as to filter particulate matter to prevent it from becoming airborne.

As the tractor continues to operate over time, as is the case with any filter, the DPF will accumulate particulate matter and will need to be cleaned. It is cleaned through a process called regeneration. During a regeneration cycle, exhaust temperatures increase to burn off the excess particulate matter. On a John Deere 5 Series Tractor equipped with a DOC/DPF, the operator does not need to provide any input to trigger the regeneration process.

Exhaust filter cleaning switch

Exhaust filter cleaning switch

On the dash is an exhaust filter cleaning switch. As long as this switch remains in the auto position, the tractor is in full control of the regeneration process and will regenerate on an as-needed basis during operation. The operator just continues to operate the tractor as normal while the regeneration process takes place.

There may be times a tractor is operating in an environment not suitable for a regeneration cycle, such as in a confined area or during service. For this reason, the bottom section of the exhaust filter cleaning switch can be depressed to disable the regeneration. The disable position allows the operator to temporarily inhibit the regeneration cycle. The operator should return the switch to auto mode as soon as possible to avoid continued soot buildup in the exhaust filter, which can lead to a parked regeneration. John Deere does not recommend disabling the automatic exhaust filter cleaning unless it is absolutely necessary.

The simplicity and intuitiveness of the exhaust filter cleaning switch maximizes uptime by minimizing the operator’s input into the regeneration process. This increases the overall productivity of the tractor by reducing the chances of a parked regeneration. The operator-friendly interface allows the operator to easily complete the task at hand, even during the regeneration process.

Intuitive controls to aide in simple operation

Adding ease to operation

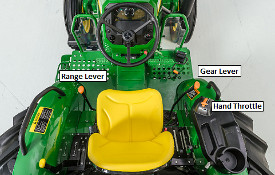

Enhanced operator controls

Enhanced operator controls

Operator comfort is important regardless of the application. Improving the 5E 3-Cylinder Tractor models, the hand throttle has been relocated to the right-hand console. This is 30.5 cm (12-in.) closer to the operator and within easy reach versus the previous location on the center-hand console. Operators may also notice the additional legroom provided by the repositioned loader controls, providing a more enjoyable experience.

9F/3R SyncShuttle™ transmission - An easy-to-use transmission which saves time and effort

Nine forward and three reverse speeds with in-line synchronized shuttle shifting

The SyncShuttle transmission is designed to match the excellent power and torque characteristics of the John Deere PowerTech™ engines. Transmission durability is enhanced with the pressure-lubricated top shaft, allowing an operator to achieve performance from one working season to the next. Additionally, this in-base transmission is configured with fixed draft links, single-speed power take-off (PTO) and mechanical PTO engagement.

The transmission is characterized as full top shaft synchronized (TSS) when forward shifting on-the-go between speeds, and is characterized a synchronized while depressing the clutch.

| 2100 engine rpm | ||

| 16.9-28 | ||

| Tire | 0.671 RR | |

| Gear | Rear Wheel Speed | Ground Speed |

| rpm | kmph | |

| A1 | 9.1 | 2.3 |

| A2 | 12.4 | 3.1 |

| A3 | 17.0 | 4.3 |

| A Rev | -13.5 | -3.4 |

| B1 | 23.1 | 5.8 |

| B2 | 31.4 | 7.9 |

| B3 | 43.2 | 10.9 |

| B Rev | -34.2 | -8.6 |

| C1 | 58.9 | 14.9 |

| C2 | 80.3 | 20.3 |

| C3 | 110.3 | 27.9 |

| C Rev | -87.3 | -22.1 |

Creeper available for R2 and R4 as field installed kit with following speeds in kmph.

| Creeper 1 | 0.40 |

| Creeper 2 | 0.54 |

| Creeper 3 | 0.75 |

| Creeper Rev | -0.59 |

Easy and comfortable shifting

Operator-friendly transmission controls with hand throttle

Operator-friendly transmission controls with hand throttle

Synchronized shifting in all forward and reverse gears

Synchronized shifting in all forward and reverse gears

Range selection pattern

Range selection pattern

Nine forward and three reverse (9F/3R) speeds are achieved by using two platform-mounted levers for shift operation. The gear lever at the operator's right hand selects one of three forward gears and one reverse gear, as well as the integrated park position. The range lever at the operator's left hand selects collar-shift A, B, and C ranges.

Operators can easily switch directions without having to completely stop the tractor with synchronized, in-line, shuttle-shift capability between forward and reverse gears on the gear-shift lever in all three ranges (A, B, and C ranges).

A neutral start switch requires the gear-shift lever be in the neutral or park positions to start the engine.

A positive park pawl on the transmission provides positive park and eliminates the need for a hand brake. This also eliminates clutch service costs that occur when the park brake is accidentally left engaged.