John Deere 600R Loader

| Make | John Deere |

| Model | 600R |

| Type | Front End Loaders for Tractors |

Your Preferred Location

Description

- Automatic Mast Latch system for easy loader removal and attachment with no tools

- Frame design that allows for maximum maneuverability

- Repositioned leveling links for improved visibility

- Remote Implement Attach feature allows quick change of loader attachments without leaving the cab

Models

Easy service with boom lockout

Hydraulic shut-off valve on R-Series Loader

Hydraulic shut-off valve on R-Series Loader

The R-Series Loaders come equipped with a hydraulic shut-off valve to improve servicabiity. When conducting brief service to the loader, close the hydraulic shut-off valve to ensure the loader does not move while operating under the equipment. This feature promotes a safe way to conduct brief maintenance without having to use support stands or removing the loader completely.

Improve appearance and reduce damage with concealed oil lines

600R Loader with concealed oil lines

600R Loader with concealed oil lines

The R-Series Loaders have been redesigned to route the oil lines and hydraulic lines through the boom arm and the torque tube. This internal routing ensures better protection of the lines from external damage and improves the overall appearance of the loader.

600R Loader (side view)

600R Loader (side view)

600R Loader (angle view)

600R Loader (angle view)

Further improve productivity with loader options

600R Loader on a 6120M Tractor

600R Loader on a 6120M Tractor

The R-Series Loaders provide several options to enhance operator experience and productivity in the field. Individual options can be ordered to fit an operation’s unique set of needs. Some of the available loader options include:

- Loader lights for enhanced visibility

- Hydraulic remote implement latch improves uptime

- Return-to-Position (RTP) Gen 2 with electronic self-leveling (ESL)

- Loader suspension system for a smoother ride

Loader lights for enhanced visibility

600R Loader with light-emitting diode (LED) lights

600R Loader with light-emitting diode (LED) lights

To further enhance visibility, the 600R Loader has the option to include LED lights. With LED lights mounted onto each side of the loader boom, performing loader applications in variable operating conditions is made easier. Pairing the loader LED light option with an LED light package on the 6110M or 6120M Tractor will provide unmatched visibility to enhance operator experience during any task.

Hydraulic remote implement latch improves uptime

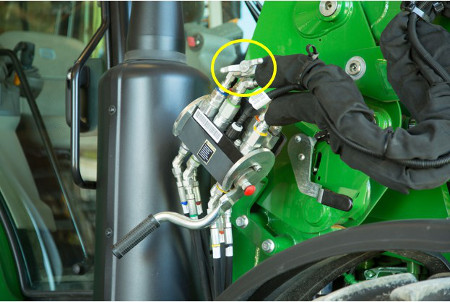

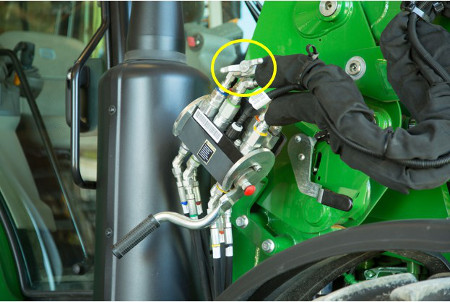

Two-button activation for hydraulic remote implement latch

Two-button activation for hydraulic remote implement latch

The hydraulic remote implement latch allows implements to be changed quickly and efficiently. An operator can activate the device from the cab by simultaneously pressing the two buttons installed on the right-hand side of the operator’s station. Switching from one attachment to the next can now be accomplished quickly with limited movements of the loader and without leaving the operator’s seat.

Return-to-Position (RTP) Gen 2 with electronic self-leveling (ESL)

Electronic loader joystick

Electronic loader joystick

The second generation of industry-exclusive RTP Gen 2 with ESL provides a practical solution for operators with daily, repetitive, material handling needs. RTP allows the operator to set different position points for the loader with the flick of the wrist, activating the detent in electronic joysticks. With the second generation of RTP, operators can set application profiles rather than entering position points each time an application is in use. RTP Gen 2 with ESL removes repetition and fatigue from loader applications.

Loader suspension system for a smoother ride

600R Loader working with a 5100R Tractor

600R Loader working with a 5100R Tractor

The loader suspension system improves operator comfort and loader efficiency during loader operation. This system is easily activated by the operator from the cab. When activated, the loader suspension system absorbs the shock providing a smoother ride in the cab as well as reducing material loss from the bucket.

Ideal tractor-loader combination with model year 2020 6110M and 6120M Tractor compatibility

Redesigned to improve compatibility

6120M Tractor with 600R Loader

6120M Tractor with 600R Loader

The 600R Loader has been redesigned to work effortlessly with the model year 2020 6110M and 6120M Tractors. The 6110M and 6120M Tractors are equipped with a sloped hood to improve operator visibility. In cadence with this updated tractor design, the 600R Loader features curved booms, making an ideal tractor-loader combination. This combination also includes a 22.9-cm (9-in.) reduction in overall machine and loader length, improving forward visibility by over 2.1 m (7 ft). Pairing the model year 2020 6110M or 6120M Tractor with the 600R Loader allows visibility directly to the loader attachment, providing more efficient performance with any loader application.

Panoramic roof for increased visibility

600R Loader through 6120M Tractor panoramic roof

600R Loader through 6120M Tractor panoramic roof

As the lift height of the R-Series Loaders increases, the panoramic roof inside of the 6M Tractor cab provides additional visibility to the entire lift-cycle of the loader. The 600R Loader has a lift height up to 391.2 cm (154 in.), allowing an operator to stack three bales. Through the larger panoramic roof of the 6M Tractor, tasks such as stacking bales can be done quickly and efficiently.

Light-emitting diode (LED) light option for variable operating conditions

600R Loader on 6110M Tractor with LED light package

600R Loader on 6110M Tractor with LED light package

To further enhance visibility, the 600R Loader has the option to include LED lights. With LED lights mounted onto each side of the loader boom, performing loader applications in variable operating conditions is made easier. Pairing the loader LED light option with an LED light package on the 6110M or 6120M Tractor will provide unmatched visibility to enhance operator experience during any task.

Easy loader removal using automatic mast latch

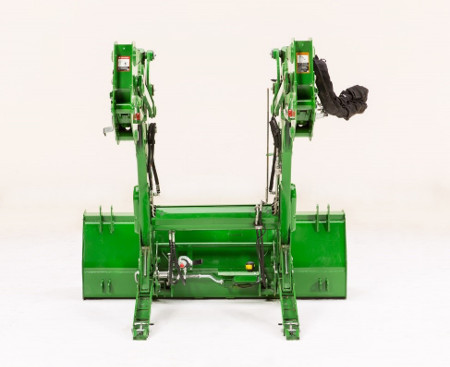

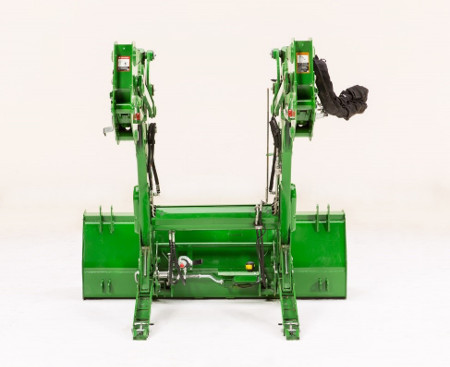

Rear view of 600R Loader

Rear view of 600R Loader

R-Series Loaders are even easier to attach and detach due to the automatic mast latch system. This feature provides efficiency to operations that require frequent loader parking. The automatic mast latch system is a mechanical lever that allows operators to remove or attach the loader with one trip out of the cab. The ease and convenience provided by the automatic mast latch system provides improvement to operation uptime.

Automatic mast latch lever

Automatic mast latch lever

Visual lock/unlock indicator

Visual lock/unlock indicator

R-Series Loader attach and detach instruction video

Faster cycle time for mechanical self-leveling (MSL) Loaders using false rod cylinders

600R Loader working with 6120M Tractor

600R Loader working with 6120M Tractor

The MSL R-Series Loaders utilize a false rod cylinder to improve bucket performance. This bucket cylinder is designed with a smaller displacement of oil required on the head end of the cylinder, which allows the cylinder to function more quickly, decreasing operation cycle time. With the false rod cylinder design, loader applications can work more quickly and efficiently.

False rod cylinders on 600R Loader

False rod cylinders on 600R Loader

Save time with single-point hydraulic connection

Single-point hydraulic connection on the 600R Loader

Single-point hydraulic connection on the 600R Loader

The R-Series Loaders feature a single-point hydraulic connection that saves the operator time when attaching or detaching the loader. This feature also incorporates the connection point for any electrical needs as well as the hydraulic lockout valve. With all hydraulic and electrical connections in one location, installation is quickly completed with the pull of a handle.

NOTE: Before disconnecting the hydraulic connection between the loader and the tractor, it is necessary to release the hydraulic pressure.

Single-point hydraulic connection (open)

Single-point hydraulic connection (open)

Single-point hydraulic connection (closed)

Single-point hydraulic connection (closed)

R-Series Loader attach and detach instruction video

Specifications

- Key Specs - Boom breakout force: Measured at pivot (Y)<br/>2665 kg<br/>5875 lb<br/>

- Key Specs - Bucket rollback force capacity: At ground-level line (ZZ)<br/>3902 kg<br/>8602 lb<br/>

- Key Specs - Clearance at full height - bucket dumped (C): 2887 mm<br/>114 in.

- Key Specs - Dump angle, degrees (E): -60 degree (angle)

- Key Specs - Lift capacity at full height: Measured at pivot (U)<br/>1875 kg<br/>4134 lb<br/>

- Key Specs - Maximum lift height (A): 3900 mm<br/>154 in.

- Key Specs - Rollback angle, degrees (G): 40 degree (angle)

- Loader - Boom breakout force: Measured at pivot (Y)<br/>2665 kg<br/>5875 lb<br/>Measured at 800 mm ahead of pivot (Z)<br/>2236 kg<br/>4930 lb<br/>

- Loader - Bucket angle: Dump angle, degrees (E)<br/>-60 degree (angle)<br/>Rollback angle, degrees (G)<br/>48 degree (angle)<br/>Dump angle, ground<br/>-100 degree (angle)<br/>

- Loader - Bucket rollback force capacity: At maximum height (VV)<br/>2548 kg<br/>5617 lb<br/>At 59-in. (1500-mm) lift height (XX)<br/>4036 kg<br/>8898 lb<br/>At ground-level line (ZZ)<br/>3902 kg<br/>8602 lbf<br/>

- Loader - Bucket used: Heavy duty

- Loader - Bucket weight: 281 kg<br/>619.5 lb

- Loader - Cycle times: Loader raise, seconds<br/>4.13 seconds<br/>Loader lower, seconds<br/>3.1 seconds<br/>Bucket dump, seconds<br/>2.58 seconds<br/>Bucket rollback, seconds<br/>2.58 seconds<br/>

- Loader - Digging depth (H): -160 mm<br/>-6 in.

- Loader - Dimensions: Maximum lift height (A)<br/>3900 mm<br/>154 in.<br/>At full height - bucket level(B)<br/>3660 mm<br/>144 in.<br/>At full height - bucket dumped (C)<br/>2887 mm<br/>114 in.<br/>

- Loader - Leveling configuration: Mechanical self-leveling (MSL)

- Loader - Lift capacity at 59 in. (1500 mm): Measured at pivot (W)<br/>2297 kg<br/>5064 lb<br/>Measured at 800 mm ahead of pivot (X)<br/>2141 kg<br/>4720 lb<br/>

- Loader - Lift capacity at full height: Measured at pivot (U)<br/>1875 kg<br/>4134 lb<br/>Measured at 800 mm ahead of pivot (V)<br/>1780 kg<br/>3924 lb<br/>

- Loader - Overall length (I+F), ft (m): 4.89 m<br/>16 ft

- Loader - Reach: At maximum height (D)<br/>942 mm<br/>154 in.<br/>At ground level - bucket level (F)<br/>2490 mm<br/>98 in.<br/>

- Tractor - Front tire: 420/70R24

- Tractor - Model: 6110M, 6120M

- Tractor - Pump capacity: 80 L/min<br/>21 gpm

- Tractor - Rated pressure: 200 bar<br/>2900.75 psi

- Tractor - Rear tire: 520/70R38

- Tractor - Wheelbase: 2400 mm<br/>94.5 in.

Features

- Lift Capacity: NSL: 5068 lbs (2299 kg) MSL: 4134 lbs (1875 kg)

- Lift Height: 154 in. (3.900 m)

Copy Set

Easy service with boom lockout

Hydraulic shut-off valve on R-Series Loader

Hydraulic shut-off valve on R-Series Loader

The R-Series Loaders come equipped with a hydraulic shut-off valve to improve servicabiity. When conducting brief service to the loader, close the hydraulic shut-off valve to ensure the loader does not move while operating under the equipment. This feature promotes a safe way to conduct brief maintenance without having to use support stands or removing the loader completely.

Improve appearance and reduce damage with concealed oil lines

600R Loader with concealed oil lines

600R Loader with concealed oil lines

The R-Series Loaders have been redesigned to route the oil lines and hydraulic lines through the boom arm and the torque tube. This internal routing ensures better protection of the lines from external damage and improves the overall appearance of the loader.

600R Loader (side view)

600R Loader (side view)

600R Loader (angle view)

600R Loader (angle view)

Further improve productivity with loader options

600R Loader on a 6120M Tractor

600R Loader on a 6120M Tractor

The R-Series Loaders provide several options to enhance operator experience and productivity in the field. Individual options can be ordered to fit an operation’s unique set of needs. Some of the available loader options include:

- Loader lights for enhanced visibility

- Hydraulic remote implement latch improves uptime

- Return-to-Position (RTP) Gen 2 with electronic self-leveling (ESL)

- Loader suspension system for a smoother ride

Loader lights for enhanced visibility

600R Loader with light-emitting diode (LED) lights

600R Loader with light-emitting diode (LED) lights

To further enhance visibility, the 600R Loader has the option to include LED lights. With LED lights mounted onto each side of the loader boom, performing loader applications in variable operating conditions is made easier. Pairing the loader LED light option with an LED light package on the 6110M or 6120M Tractor will provide unmatched visibility to enhance operator experience during any task.

Hydraulic remote implement latch improves uptime

Two-button activation for hydraulic remote implement latch

Two-button activation for hydraulic remote implement latch

The hydraulic remote implement latch allows implements to be changed quickly and efficiently. An operator can activate the device from the cab by simultaneously pressing the two buttons installed on the right-hand side of the operator’s station. Switching from one attachment to the next can now be accomplished quickly with limited movements of the loader and without leaving the operator’s seat.

Return-to-Position (RTP) Gen 2 with electronic self-leveling (ESL)

Electronic loader joystick

Electronic loader joystick

The second generation of industry-exclusive RTP Gen 2 with ESL provides a practical solution for operators with daily, repetitive, material handling needs. RTP allows the operator to set different position points for the loader with the flick of the wrist, activating the detent in electronic joysticks. With the second generation of RTP, operators can set application profiles rather than entering position points each time an application is in use. RTP Gen 2 with ESL removes repetition and fatigue from loader applications.

Loader suspension system for a smoother ride

600R Loader working with a 5100R Tractor

600R Loader working with a 5100R Tractor

The loader suspension system improves operator comfort and loader efficiency during loader operation. This system is easily activated by the operator from the cab. When activated, the loader suspension system absorbs the shock providing a smoother ride in the cab as well as reducing material loss from the bucket.

Ideal tractor-loader combination with model year 2020 6110M and 6120M Tractor compatibility

Redesigned to improve compatibility

6120M Tractor with 600R Loader

6120M Tractor with 600R Loader

The 600R Loader has been redesigned to work effortlessly with the model year 2020 6110M and 6120M Tractors. The 6110M and 6120M Tractors are equipped with a sloped hood to improve operator visibility. In cadence with this updated tractor design, the 600R Loader features curved booms, making an ideal tractor-loader combination. This combination also includes a 22.9-cm (9-in.) reduction in overall machine and loader length, improving forward visibility by over 2.1 m (7 ft). Pairing the model year 2020 6110M or 6120M Tractor with the 600R Loader allows visibility directly to the loader attachment, providing more efficient performance with any loader application.

Panoramic roof for increased visibility

600R Loader through 6120M Tractor panoramic roof

600R Loader through 6120M Tractor panoramic roof

As the lift height of the R-Series Loaders increases, the panoramic roof inside of the 6M Tractor cab provides additional visibility to the entire lift-cycle of the loader. The 600R Loader has a lift height up to 391.2 cm (154 in.), allowing an operator to stack three bales. Through the larger panoramic roof of the 6M Tractor, tasks such as stacking bales can be done quickly and efficiently.

Light-emitting diode (LED) light option for variable operating conditions

600R Loader on 6110M Tractor with LED light package

600R Loader on 6110M Tractor with LED light package

To further enhance visibility, the 600R Loader has the option to include LED lights. With LED lights mounted onto each side of the loader boom, performing loader applications in variable operating conditions is made easier. Pairing the loader LED light option with an LED light package on the 6110M or 6120M Tractor will provide unmatched visibility to enhance operator experience during any task.

Easy loader removal using automatic mast latch

Rear view of 600R Loader

Rear view of 600R Loader

R-Series Loaders are even easier to attach and detach due to the automatic mast latch system. This feature provides efficiency to operations that require frequent loader parking. The automatic mast latch system is a mechanical lever that allows operators to remove or attach the loader with one trip out of the cab. The ease and convenience provided by the automatic mast latch system provides improvement to operation uptime.

Automatic mast latch lever

Automatic mast latch lever

Visual lock/unlock indicator

Visual lock/unlock indicator

Faster cycle time for mechanical self-leveling (MSL) Loaders using false rod cylinders

600R Loader working with 6120M Tractor

600R Loader working with 6120M Tractor

The MSL R-Series Loaders utilize a false rod cylinder to improve bucket performance. This bucket cylinder is designed with a smaller displacement of oil required on the head end of the cylinder, which allows the cylinder to function more quickly, decreasing operation cycle time. With the false rod cylinder design, loader applications can work more quickly and efficiently.

False rod cylinders on 600R Loader

False rod cylinders on 600R Loader

Save time with single-point hydraulic connection

Single-point hydraulic connection on the 600R Loader

Single-point hydraulic connection on the 600R Loader

The R-Series Loaders feature a single-point hydraulic connection that saves the operator time when attaching or detaching the loader. This feature also incorporates the connection point for any electrical needs as well as the hydraulic lockout valve. With all hydraulic and electrical connections in one location, installation is quickly completed with the pull of a handle.

NOTE: Before disconnecting the hydraulic connection between the loader and the tractor, it is necessary to release the hydraulic pressure.

Single-point hydraulic connection (open)

Single-point hydraulic connection (open)

Single-point hydraulic connection (closed)

Single-point hydraulic connection (closed)