John Deere 440R Loader

| Make | John Deere |

| Model | 440R |

| Type | Front End Loaders for Tractors |

Your Preferred Location

Description

- Compatible with 4R Series Tractors and older 4 Series Tractors of similar size

- Quik-Park™ loader mounting system for fast, easy attachment and removal

- Quik-Change™ attachment carrier makes switching from chore to chore a snap

- Optional skid steer attachment carrier

Models

Optional skid steer attachment carrier

Optional skid steer attachment carrier

Optional skid steer attachment carrier

The skid steer attachment carrier is installed in place of the standard John Deere attachment carrier and allows for the use of skid steer attachments on the 440R, H180, H160, and H165 Loaders.

Skid steer attachments are available through Worksite Pro™ attachments.

Loader suspension system (LSS) to enhance the ride

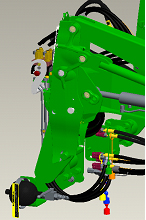

Nitrogen-charged accumulator and electric valve

Nitrogen-charged accumulator and electric valve

Operator on/off switch

Operator on/off switch

LSS on H180

LSS on H180

LSS on 5E and 5M

LSS on 5E and 5M

An enhancement to the loader is the suspension system. A great level of loader productivity is achieved with the LSS.

- An accumulator charged with nitrogen and connected to the head-end lift cylinder hose through a T-fitting provides shock absorption

- The cylinders move in and out to allow the boom to float

Performance

- Bales can be transported more efficiently from one end of the field to the other over frozen, hard-packed, or rutted terrain.

NOTE: Check bale-handling capability of tractor before use.

- Pallets can be moved easily without sustaining cargo damage

- Pallets of seed or fertilizer can be carried across a yard without a bag spilling and creating a costly mess

- A properly-ballasted tractor with LSS has increased stability, creating a smoother ride for the operator

Cost of ownership

-

Extended life of loader pins and bushings

-

Less stress on tractor axle

Reasons for turning LSS off include:

- Digging applications - with LSS on, the cylinders retract slightly, losing lifting power

- Holding a grade when blading - with LSS on, it is difficult to hold a constant grade

- Precise pallet and bale handling - with LSS on, the load moves up and down slightly while being positioned

- Parking a loader - with LSS on, when down pressure is applied, the lift cylinders retract slightly, making it more difficult to park

The switch is conveniently located in the operator station to avoid having to exit the tractor seat to manually move the handle on the LSS.

LSS can also be ordered with a manual shutoff. Depending on the tractor/loader model, the accumulator is located in different places. On the 440R, the accumulator is mounted outside the bottom of the mounting frame. On the 5 Series Tractors, the accumulator is mounted near the inside of the rear right wheel. On 6 Series tractors and larger, it is mounted in between the hydraulic connection and the mounting frame.

Quik-Park™ loader mounting system

Quik-Park loader mounting system

Quik-Park loader mounting system

The 440R Loader is designed for easy removal and mounting to and from the tractor without tools.

Parking stand

Parking stand

The parking stand, attached to the front frame of the tractor, is an integral part of the loader during loader operation.

The parking stand lowers into position by moving the joystick to the raised position once the latches are opened. This allows the loader to move to the park position.

Tractor backing away

Tractor backing away

Quik-Change attachment carrier

Easy removal and mounting of attachments

Easy removal and mounting of attachments

Close up of Quik-Change attachment mounting

Close up of Quik-Change attachment mounting

The Quik-Change attachment carrier allows for fast, easy removal and mounting of attachments without tools.

Specifications

- Key Specs - Boom breakout force: Measured at pivot (Y)<br/>1743.7 kgf<br/>3835 lbf<br/>Measured at 500 mm ahead of pivot (Z)<br/>1517 kgf<br/>3337 lbf<br/>

- Key Specs - Bucket rollback force capacity: At ground-level line (ZZ)<br/>2101 kgf<br/>4622 lbf<br/>

- Key Specs - Clearance at full height - bucket dumped (C): 2178 mm<br/>86 in.

- Key Specs - Dump angle, degrees (E): 46.6 degree (angle)

- Key Specs - Lift capacity at full height: Measured at pivot (U)<br/>1006 kg<br/>2313 lb<br/>Measured at 500 mm ahead of pivot (V)<br/>1010 kg<br/>2222 lb<br/>

- Key Specs - Maximum lift height (A): 2796 mm<br/>110 in.

- Key Specs - Rollback angle, degrees (G): 38.4 degree (angle)

- Loader - Base weight: 302 kg

- Loader - Boom breakout force: Measured at pivot (Y)<br/>1743.7 kgf<br/>3835 lbf<br/>Measured at 500 mm ahead of pivot (Z)<br/>1517 kgf<br/>3337 lbf<br/>

- Loader - Bucket angle: Dump angle, degrees (E)<br/>46.6 degree (angle)<br/>Rollback angle, degrees (G)<br/>38.4 degree (angle)<br/>Dump angle, ground<br/>129.54 degree (angle)<br/>

- Loader - Bucket rollback force capacity: At maximum height (VV)<br/>1542 kgf<br/>3480 lbf<br/>At 59-in. (1500-mm) lift height (XX)<br/>2249 kgf<br/>4948 lbf<br/>At ground-level line (ZZ)<br/>2101 kgf<br/>4622 lbf<br/>

- Loader - Bucket used: Materials - 73 in.

- Loader - Bucket weight: 146 kg<br/>321 lb

- Loader - Cycle times: Loader raise, seconds<br/>2.41 seconds<br/>Loader lower, seconds<br/>1.62 seconds<br/>Bucket dump, seconds<br/>2.46 seconds<br/>Bucket rollback, seconds<br/>1.65 seconds<br/>

- Loader - Digging depth (H): 122 mm<br/>5 in.

- Loader - Dimensions: Maximum lift height (A)<br/>2796 mm<br/>110 in.<br/>At full height - bucket level(B)<br/>2590 mm<br/>102 in.<br/>At full height - bucket dumped (C)<br/>2178 mm<br/>86 in.<br/>

- Loader - Leveling configuration: Mechanical Self-Leveling

- Loader - Lift capacity at 59 in. (1500 mm): Measured at pivot (W)<br/>1263 kg<br/>2779 lb<br/>Measured at 500 mm ahead of pivot (X)<br/>1201 kg<br/>2642 lb<br/>

- Loader - Lift capacity at full height: Measured at pivot (U)<br/>1006 kg<br/>2213 lb<br/>Measured at 500 mm ahead of pivot (V)<br/>1010 kg<br/>2222 lb<br/>

- Loader - Overall height in carry position (J): 1.53 m<br/>5 ft

- Loader - Overall length (I+F), ft (m): 3.54 m<br/>11.7 ft

- Loader - Reach: At maximum height (D)<br/>755 mm<br/>30 in.<br/>At ground level - bucket level (F)<br/>1703 mm<br/>67 in.<br/>

- Tractor - Front tire: 25x8-16 6PR R1 T1

- Tractor - Model: 4044R, 4049R, 4052R, 4066R

- Tractor - Pump capacity: 15.9 gpm<br/>60.2 L/min

- Tractor - Rated pressure: 2499 psi<br/>17.2 MPa

- Tractor - Rear tire: 13.8-28 4PR R1 T1

- Tractor - Wheelbase: 1846 mm<br/>73 in.

Features

- Lift Height: 109-110 in. (2.767-2.799 m)

- Lift Capacity: 1,846-1,885 lbs (839-857 kg)

Copy Set

Optional skid steer attachment carrier

Optional skid steer attachment carrier

Optional skid steer attachment carrier

The skid steer attachment carrier is installed in place of the standard John Deere attachment carrier and allows for the use of skid steer attachments on the 440R, H180, H160, and H165 Loaders.

Skid steer attachments are available through Worksite Pro™ attachments.

Loader suspension system (LSS) to enhance the ride

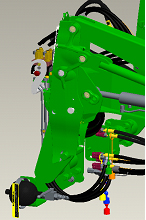

Nitrogen-charged accumulator and electric valve

Nitrogen-charged accumulator and electric valve

Operator on/off switch

Operator on/off switch

LSS on H180

LSS on H180

LSS on 5E and 5M

LSS on 5E and 5M

An enhancement to the loader is the suspension system. A great level of loader productivity is achieved with the LSS.

- An accumulator charged with nitrogen and connected to the head-end lift cylinder hose through a T-fitting provides shock absorption

- The cylinders move in and out to allow the boom to float

Performance

- Bales can be transported more efficiently from one end of the field to the other over frozen, hard-packed, or rutted terrain.

NOTE: Check bale-handling capability of tractor before use.

- Pallets can be moved easily without sustaining cargo damage

- Pallets of seed or fertilizer can be carried across a yard without a bag spilling and creating a costly mess

- A properly-ballasted tractor with LSS has increased stability, creating a smoother ride for the operator

Cost of ownership

-

Extended life of loader pins and bushings

-

Less stress on tractor axle

Reasons for turning LSS off include:

- Digging applications - with LSS on, the cylinders retract slightly, losing lifting power

- Holding a grade when blading - with LSS on, it is difficult to hold a constant grade

- Precise pallet and bale handling - with LSS on, the load moves up and down slightly while being positioned

- Parking a loader - with LSS on, when down pressure is applied, the lift cylinders retract slightly, making it more difficult to park

The switch is conveniently located in the operator station to avoid having to exit the tractor seat to manually move the handle on the LSS.

LSS can also be ordered with a manual shutoff. Depending on the tractor/loader model, the accumulator is located in different places. On the 440R, the accumulator is mounted outside the bottom of the mounting frame. On the 5 Series Tractors, the accumulator is mounted near the inside of the rear right wheel. On 6 Series tractors and larger, it is mounted in between the hydraulic connection and the mounting frame.

Quik-Park™ loader mounting system

Quik-Park loader mounting system

Quik-Park loader mounting system

The 440R Loader is designed for easy removal and mounting to and from the tractor without tools.

Parking stand

Parking stand

The parking stand, attached to the front frame of the tractor, is an integral part of the loader during loader operation.

The parking stand lowers into position by moving the joystick to the raised position once the latches are opened. This allows the loader to move to the park position.

Tractor backing away

Tractor backing away

Quik-Change attachment carrier

Easy removal and mounting of attachments

Easy removal and mounting of attachments

Close up of Quik-Change attachment mounting

Close up of Quik-Change attachment mounting

The Quik-Change attachment carrier allows for fast, easy removal and mounting of attachments without tools.