John Deere 120R Loader

| Make | John Deere |

| Model | 120R |

| Type | Front End Loaders for Tractors |

Your Preferred Location

Description

- Compatible with the 1023E, 1025R and 2025R tractors

- Quik-Park stands for easy attachment and removal

- up to 553 lb (251 kg) lift capacity

- Mechanical Self-Leveling (MSL) Loader option with up to 726 lb (330 kg) lift capacity

Models

End-of-pin lubrication on cylinder and pivot pins allows easy access for servicing grease points

Pivot pin

Pivot pin

Pivot pins shown on the 120R Loader

Pivot pins shown on the 120R Loader

The unique offset head design eliminates cross-pins and cotter pins to retain the pin.

A nut ensures the pins remain in position.

A lubrication groove provides a path for lubrication.

End-of-pin lubrication allows easy access for servicing grease points, which are visible from the side of the loader.

Easily remove and mount loader to and from the tractor without tools

Quik-Park™ loader mounting system

Quik-Park™ loader mounting system

The Quik-Park mounting system on the 120R Loader is designed for easy removal and mounting to and from the tractor without tools.

Just like on the former H120, the parking stand is attached to the mast. To lower it into the park position, simply move the joystick to the raise position once the latches are opened.

Mount to and from the tractor without tools

Mount to and from the tractor without tools

D120

Parking stands stored in the D120 torque tube

Parking stands stored in the D120 torque tube

The D120 does not utilize the Quik-Park system as used on the 120R, but rather has two parking stands that are stored within the torque tube for a manual parking process.

Remove the parking stand from the torque tube area and place within the loader foot plate during the parking process (as shown).

Once the loader weight is being supported by the bucket and parking stands, manually remove the pins from the mast assembly and disconnect hydraulics.

Remove the parking pins

Remove the parking pins

Back away from the loader

Back away from the loader

After installing the parking stands, removing the parking pins and disconnecting hydraulics, simply back away.

D120 Loader on the parking stands

D120 Loader on the parking stands

Operate with ease and efficiency using the optional field-installed mechanical self-leveling (MSL) loader

Whether the operator is new or experienced to loader operations, it requires skill to maintain an even load and reduce the amount of material lost. With the MSL loader offering for 1 Family, 2 Family, 3D, and 3E Tractors, anyone can operate their loader with ease and confidence. With the MSL loader, you will notice:

- Loader implement will maintain position wherever the loader is lifted to

- Increased lift capacities

- Reduction of material lost during operation

- Easy visibility of the bucket level indicator on the right-hand side of the loader boom to help determine the position of the front implement

This loader is the first of its kind in North America for Compact Utility Tractors and can make any loader task easier and quicker to accomplish.

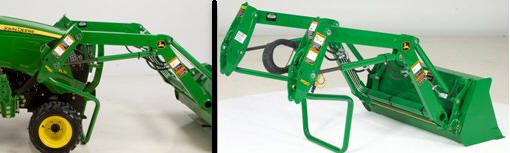

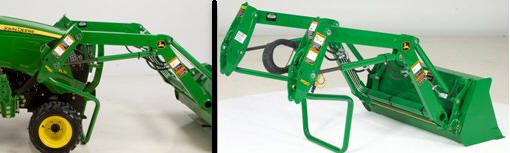

Studio rendering of 1R Tractor with 120R MSL Loader

Studio rendering of 1R Tractor with 120R MSL Loader

Pallet fork usage rendering of 1R Tractor with 120R MSL Loader

Pallet fork usage rendering of 1R Tractor with 120R MSL Loader

Specifications

- Key Specs - Boom breakout force: Measured at pivot (Y)<br/>890 kgf<br/>1963 lbf<br/>Measured at 500 mm ahead of pivot (Z)<br/>606 kgf<br/>1335 lbf<br/>

- Key Specs - Bucket rollback force capacity: At ground-level line (ZZ)<br/>753 kgf<br/>1659 lbf<br/>

- Key Specs - Clearance at full height - bucket dumped (C): 1304 mm<br/>51.3 in.

- Key Specs - Dump angle, degrees (E): -40.5 degree (angle)

- Key Specs - Lift capacity at full height: Measured at pivot (U)<br/>364 kg<br/>803 lb<br/>Measured at 500 mm ahead of pivot (V)<br/>251 kg<br/>553 lb<br/>

- Key Specs - Maximum lift height (A): 1828 mm<br/>72 in.

- Key Specs - Rollback angle, degrees (G): 30.08 degree (angle)

- Loader - Base weight: 283.88 kg

- Loader - Boom breakout force: Measured at pivot (Y)<br/>890 kgf<br/>1963 lbf<br/>Measured at 500 mm ahead of pivot (Z)<br/>606 kgf<br/>1335 lbf<br/>

- Loader - Bucket angle: Dump angle, degrees (E)<br/>-40.5 degree (angle)<br/>Rollback angle, degrees (G)<br/>30.08 degree (angle)<br/>Dump angle, ground<br/>-115.4 degree (angle)<br/>

- Loader - Bucket rollback force capacity: At maximum height (VV)<br/>648 kgf<br/>1428 lbf<br/>At 59-in. (1500-mm) lift height (XX)<br/>777 kgf<br/>1713 lbf<br/>At ground-level line (ZZ)<br/>753 kgf<br/>1659 lbf<br/>

- Loader - Bucket used: Materials 1350 mm

- Loader - Bucket weight: 83 kg<br/>183 lb

- Loader - Cycle times: Loader raise, seconds<br/>3.7 seconds<br/>Loader lower, seconds<br/>2.6 seconds<br/>Bucket dump, seconds<br/>4.1 seconds<br/>Bucket rollback, seconds<br/>2.5 seconds<br/>

- Loader - Digging depth (H): -86 mm<br/>-3.4 in.

- Loader - Dimensions: Maximum lift height (A)<br/>1828 mm<br/>72 in.<br/>At full height - bucket level(B)<br/>1666 mm<br/>65.6 in.<br/>At full height - bucket dumped (C)<br/>1304 mm<br/>51.3 in.<br/>

- Loader - Lift capacity at 59 in. (1500 mm): Measured at pivot (W)<br/>434 kg<br/>957 lb<br/>Measured at 500 mm ahead of pivot (X)<br/>312 kg<br/>688 lb<br/>

- Loader - Lift capacity at full height: Measured at pivot (U)<br/>364 kg<br/>803 lb<br/>Measured at 500 mm ahead of pivot (V)<br/>251 kg<br/>553 lb<br/>

- Loader - Overall length (I+F), ft (m): 2888 mm<br/>113.7 in.

- Loader - Reach: At maximum height (D)<br/>698 mm<br/>27.5 in.<br/>At ground level - bucket level (F)<br/>1288 mm<br/>50.7 in.<br/>

- Tractor - Front tire: 23x8.50-12 6PR R4 CL

- Tractor - Model: 2025R/2026R

- Tractor - Pump capacity: 26.5 L/min

- Tractor - Rated pressure: 2146 psi

- Tractor - Rear tire: 12.00-16.5 6PR R4 CL

- Tractor - Wheelbase: 1600 mm

Features

- Lift Capacity: 1025R: 517 lbs (235 kg) 2025R: 553 lbs (251 kg)

- Lift Height: 1025R: 72 in. (1828 mm) 2025R: 72 in. (1828mm)

Copy Set

End-of-pin lubrication on cylinder and pivot pins allows easy access for servicing grease points

Pivot pin

Pivot pin

Pivot pins shown on the 120R Loader

Pivot pins shown on the 120R Loader

The unique offset head design eliminates cross-pins and cotter pins to retain the pin.

A nut ensures the pins remain in position.

A lubrication groove provides a path for lubrication.

End-of-pin lubrication allows easy access for servicing grease points, which are visible from the side of the loader.

Easily remove and mount loader to and from the tractor without tools

Quik-Park™ loader mounting system

Quik-Park™ loader mounting system

The Quik-Park mounting system on the 120R Loader is designed for easy removal and mounting to and from the tractor without tools.

Just like on the former H120, the parking stand is attached to the mast. To lower it into the park position, simply move the joystick to the raise position once the latches are opened.

Mount to and from the tractor without tools

Mount to and from the tractor without tools

D120

Parking stands stored in the D120 torque tube

Parking stands stored in the D120 torque tube

The D120 does not utilize the Quik-Park system as used on the 120R, but rather has two parking stands that are stored within the torque tube for a manual parking process.

Remove the parking stand from the torque tube area and place within the loader foot plate during the parking process (as shown).

Once the loader weight is being supported by the bucket and parking stands, manually remove the pins from the mast assembly and disconnect hydraulics.

Remove the parking pins

Remove the parking pins

Back away from the loader

Back away from the loader

After installing the parking stands, removing the parking pins and disconnecting hydraulics, simply back away.

D120 Loader on the parking stands

D120 Loader on the parking stands

Operate with ease and efficiency using the optional field-installed mechanical self-leveling (MSL) loader

Whether the operator is new or experienced to loader operations, it requires skill to maintain an even load and reduce the amount of material lost. With the MSL loader offering for 1 Family, 2 Family, 3D, and 3E Tractors, anyone can operate their loader with ease and confidence. With the MSL loader, you will notice:

- Loader implement will maintain position wherever the loader is lifted to

- Increased lift capacities

- Reduction of material lost during operation

- Easy visibility of the bucket level indicator on the right-hand side of the loader boom to help determine the position of the front implement

This loader is the first of its kind in North America for Compact Utility Tractors and can make any loader task easier and quicker to accomplish.

Studio rendering of 1R Tractor with 120R MSL Loader

Studio rendering of 1R Tractor with 120R MSL Loader

Pallet fork usage rendering of 1R Tractor with 120R MSL Loader

Pallet fork usage rendering of 1R Tractor with 120R MSL Loader