John Deere 180A Auger Platform

Description

- Heavy-duty knife drive and cutterbar for increased reliability

- Heavy-duty multi-bat reel improves crop flow

- Adjustable reel-cam track to control crop release

- Header index ensures optimum platform speeds

Models

Adjustable reel-cam track to control crop release

Cam track

Cam track

The reel cam is easily adjusted to match crop release to varying crop conditions, such as light to heavy crop.

Cam-forward reel-tine control reduces the load on bearings and cam track for quieter, smoother operation and longer life. The higher position of the cam itself helps to keep it above the crop and away from debris. The smoother operation allows for operation speeds of up to 13 km/h (8 mph).

Heavy-duty, multi-bat reel improves crop flow

Heavy-duty reel

Heavy-duty reel

The 100A Windrower Platforms are built to meet the needs of a large producer or commercial hay grower.

Large-diameter, 6.35 mm (1/4-in.) reel teeth are stiff enough to maintain control of the crop from the cutterbar to the augers for even feeding, especially in heavy crop conditions. The teeth nearest to the reel cam are formed to improve crop flow by the reel ends.

The operator can easily control the reel speed from 15 rpm to 85 rpm.

The teeth are designed to lift lodged and tangled material, then draw it against the cutterbar for close, clean cutting in any direction.

Reel bat

Reel bat

Reel bats are made of oval tubing. The oval-tube reel bats increase the rigidity and strength of the reel.

The bats are equipped with end caps and remain free from foreign material, reducing unnecessary loads on the reel.

Standard 100A Windrower Platforms feature six bat reels. The 160A Grass Seed Windrower Platforms feature a seven-bat reel.

Header index ensures optimum platform speeds

Header index control

Header index control

The header index adjusts the reel speeds in relationship to the windrower ground speed; the operator can focus on the platform position instead of adjusting the reel speed as the windrower speed changes due to field conditions. The index feature maintains a preselected speed based on the ground speed plus an easily adjusted index number. This ensures that when the operator sets the index, the reel will turn fast enough to ensure proper crop flow.

Center-feed auger with poly auger pans for improved crop flow

Large 508-mm (20-in.) auger

Large 508-mm (20-in.) auger

Poly auger pan

Poly auger pan

The 508-mm (20-in.) center-feed augers are positioned over replaceable, high-density polyethylene auger pans. Rubber feed fingers and a direct-mounted hydraulic motor ensure optimum performance.

Crop feeding is enhanced by the 100A Platform’s poly feed pan design, progressive feed paddles, and unique stripper bars, which combine to allow for smooth feeding even in adverse conditions. The poly auger pan reduces mud buildup, improves crop flow, and is easier to clean. The poly is longer lasting than other transition pan materials, as well as less susceptible to rock damage. The feed pan is made of two separate bolted-in sheets of poly. This sectional design allows for easier replacement than steel feed pans.

Feed fingers

Feed fingers

The center-mounted rubber fingers keep crop moving consistently into the conditioner.

NOTE: The 160A Grass Seed Windrower Platform does not have a conditioner.

Heavy-duty knife drive and cutterbar for increased reliability

Z-shaped cutterbar

Z-shaped cutterbar

The 100A Windrower Platforms have a twin-knife design.

The twin-knife design uses two counter-stroking knives with two sections that overlap in the center of the platform. The advantages of this design are as follows:

- Reduces cutting loads for increased reliability

- Easier to remove and handle short knives for normal maintenance

- Adjustable from 1400 to 1950 strokes per minute for clean cutting at productive ground speeds

- Counter-stroking reduces vibration

The Z-shaped profile of the cutterbar, along with rectangular reinforcement, improves the durability of the cutterbar along both the horizontal and vertical planes, allowing it to better withstand impact from field obstacles.

Adjust windrow width to meet drying requirements

Windrow adjustment

Windrow adjustment

Right-hand and left-hand windrow-forming shields are easily adjusted from the rear of the unit.

Independent adjustment of the forming shields gives the operator more control over the windrow formation. This is a simple, no-tool adjustment.

The windrow width is adjustable from a narrow, 0.9-m (3-ft) swath to a wide, fast-drying, 2.3-m (7.67-ft) swath, depending on crop conditions.

The rear fluff shield enables further control over the shape of the windrow.

Durable steel conditioner rolls for long life

Steel conditioning rollers

Steel conditioning rollers

The A-Series conditioner rolls are a full 2591-mm (102-in.) wide for crimping performance and ensure thorough conditioning of the plant stem. The use of the steel-on-steel intermeshing roll design ensures that leaves are retained for high protein value, providing high-quality hay, forage, and alfalfa crops. The straight design of these conditioner rolls makes them easy to repair, as damaged sections can easily be cut out and replaced.

The rolls are powered by a hydraulic motor with an adjustable speed from 601 rpm to 790 rpm. The steel rolls offer improved wear life, particularly in adverse soil and crop conditions.

Optional reverser clears plugs effortlessly for higher productivity during tough harvest conditions

Platform reverser controls on W155

Platform reverser controls on W155

Platform reverser controls are available for the W155 Self-Propelled Windrower only:

- Easily activated from operator's station to clear platform of plugs

- Reverser slowly reverses the knife drive and optional hay conditioner, if equipped, to clear plugs

- Highly recommended when using optional hay conditioner with 400D Platforms

- Operators can run machines closer to their maximum capacity and it will take less time to unplug

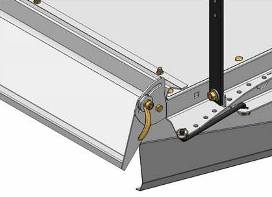

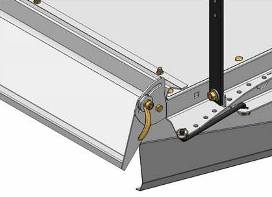

Reverser valve block

Reverser valve block

The reverser consists of a valve block and valves, shown in the image above. It is the gold-colored valve block on the right side. It is shown plumbed for a 100A Auger Platform.

Rock-drop opening protects conditioner rolls

Drop-out area

Drop-out area

Located below the auger and in front of the conditioner rolls, the rock-drop opening allows rocks and other obstructions to drop out before reaching the conditioning rolls while still ensuring proper crop flow. The rock-drop feature helps to protect the platform's internal components from damage, which will increase uptime and productivity. It also allows sand, soil, and debris to drop out below the windrow for higher-quality crop and less foreign material in the windrow.

Specifications

- Angled-steel conditioner rolls - Diameter: 233 mm<br/>9.17 in.

- Angled-steel conditioner rolls - Drive: Hydraulic motor to enclosed gearbox

- Angled-steel conditioner rolls - Length: 2590 mm<br/>102 in.

- Angled-steel conditioner rolls - Speed: 601 - 790, variable hydraulic rpm

- Angled-steel conditioner rolls - Type: Intermeshing steel rolls

- Augers - Diameter: <br/><br/>508, single auger mm<br/>20, single auger in.

- Augers - Drive: <br/><br/>Hydraulic direct -drive

- Augers - Speed: <br/><br/>230 - 320, variable hydraulic rpm

- Cutterbar - Drive: Timed dual knife

- Cutterbar - Guards: Two-tine, double heat treated forged pointed guards, Non-clog guards optional

- Cutterbar - Knife (chrome): Over-serrated, 9 serrations per inch or 14 serrations per inch available

- Cutterbar - Speed: Variable, 1450 - 1900 spm

- Dimensions - Platform cutting width: 5.41 m<br/>17, 9 ft, in.

- Dimensions - Platform overall width: 5.87 m<br/>19, 3 ft, in.

- Dimensions - Platform weight: 2733 kg<br/>6020 lb

- Dimensions - Windrow width (depending on crop conditions): 915 - 2540 mm<br/>36 - 100 in.

- Hydraulically driven, variable-speed reel - Adjustable: Up and down, fore and aft

- Hydraulically driven, variable-speed reel - Diameter: 1080 mm<br/>44 in.

- Hydraulically driven, variable-speed reel - Drive: Hydraulic

- Hydraulically driven, variable-speed reel - Tooth bars: Six sectioned with regreasable bearings and six reel bats w/ end caps, 7th bat available for dealer inst.

- Hydraulically driven, variable-speed reel - Variable speed: 51-85 rpm

- Key Specs - Angled-steel conditioner rolls - Type: Intermeshing steel rolls

- Key Specs - Augers - Diameter: Single auger: 508 mm<br/>20 in.

- Key Specs - Compatibility: W110 and W150 Windrowers

- Key Specs - Cutterbar - Drive: Timed dual knife

- Key Specs - Cutterbar - Speed: Variable, 1450 - 1900 spm

- Key Specs - Knife (chrome): Over-serrated, 9 serrations per inch or 14 serrations per inch available

- Key Specs - Platform cutting width: 5.41 m<br/>17.75 ft

- Key Specs - Platform overall width: 5.87 m<br/>19.25 ft

- Key Specs - Platform weight: 2733 kg<br/>6020 lb

- Key Specs - Windrow width (depending on crop conditions): 915 - 2540 mm<br/>36 - 100 in.

- Windrower - Compatibility: W110 and W150 Windrowers

- Windrower - Formation: Adjustable swathboard (plus adjustable forming shields on windrower)

Copy Set

Adjustable reel-cam track to control crop release

Cam track

Cam track

The reel cam is easily adjusted to match crop release to varying crop conditions, such as light to heavy crop.

Cam-forward reel-tine control reduces the load on bearings and cam track for quieter, smoother operation and longer life. The higher position of the cam itself helps to keep it above the crop and away from debris. The smoother operation allows for operation speeds of up to 13 km/h (8 mph).

Heavy-duty, multi-bat reel improves crop flow

Heavy-duty reel

Heavy-duty reel

The 100A Windrower Platforms are built to meet the needs of a large producer or commercial hay grower.

Large-diameter, 6.35 mm (1/4-in.) reel teeth are stiff enough to maintain control of the crop from the cutterbar to the augers for even feeding, especially in heavy crop conditions. The teeth nearest to the reel cam are formed to improve crop flow by the reel ends.

The operator can easily control the reel speed from 15 rpm to 85 rpm.

The teeth are designed to lift lodged and tangled material, then draw it against the cutterbar for close, clean cutting in any direction.

Reel bat

Reel bat

Reel bats are made of oval tubing. The oval-tube reel bats increase the rigidity and strength of the reel.

The bats are equipped with end caps and remain free from foreign material, reducing unnecessary loads on the reel.

Standard 100A Windrower Platforms feature six bat reels. The 160A Grass Seed Windrower Platforms feature a seven-bat reel.

Header index ensures optimum platform speeds

Header index control

Header index control

The header index adjusts the reel speeds in relationship to the windrower ground speed; the operator can focus on the platform position instead of adjusting the reel speed as the windrower speed changes due to field conditions. The index feature maintains a preselected speed based on the ground speed plus an easily adjusted index number. This ensures that when the operator sets the index, the reel will turn fast enough to ensure proper crop flow.

Center-feed auger with poly auger pans for improved crop flow

Large 508-mm (20-in.) auger

Large 508-mm (20-in.) auger

Poly auger pan

Poly auger pan

The 508-mm (20-in.) center-feed augers are positioned over replaceable, high-density polyethylene auger pans. Rubber feed fingers and a direct-mounted hydraulic motor ensure optimum performance.

Crop feeding is enhanced by the 100A Platform’s poly feed pan design, progressive feed paddles, and unique stripper bars, which combine to allow for smooth feeding even in adverse conditions. The poly auger pan reduces mud buildup, improves crop flow, and is easier to clean. The poly is longer lasting than other transition pan materials, as well as less susceptible to rock damage. The feed pan is made of two separate bolted-in sheets of poly. This sectional design allows for easier replacement than steel feed pans.

Feed fingers

Feed fingers

The center-mounted rubber fingers keep crop moving consistently into the conditioner.

NOTE: The 160A Grass Seed Windrower Platform does not have a conditioner.

Heavy-duty knife drive and cutterbar for increased reliability

Z-shaped cutterbar

Z-shaped cutterbar

The 100A Windrower Platforms have a twin-knife design.

The twin-knife design uses two counter-stroking knives with two sections that overlap in the center of the platform. The advantages of this design are as follows:

- Reduces cutting loads for increased reliability

- Easier to remove and handle short knives for normal maintenance

- Adjustable from 1400 to 1950 strokes per minute for clean cutting at productive ground speeds

- Counter-stroking reduces vibration

The Z-shaped profile of the cutterbar, along with rectangular reinforcement, improves the durability of the cutterbar along both the horizontal and vertical planes, allowing it to better withstand impact from field obstacles.

Adjust windrow width to meet drying requirements

Windrow adjustment

Windrow adjustment

Right-hand and left-hand windrow-forming shields are easily adjusted from the rear of the unit.

Independent adjustment of the forming shields gives the operator more control over the windrow formation. This is a simple, no-tool adjustment.

The windrow width is adjustable from a narrow, 0.9-m (3-ft) swath to a wide, fast-drying, 2.3-m (7.67-ft) swath, depending on crop conditions.

The rear fluff shield enables further control over the shape of the windrow.

Durable steel conditioner rolls for long life

Steel conditioning rollers

Steel conditioning rollers

The A-Series conditioner rolls are a full 2591-mm (102-in.) wide for crimping performance and ensure thorough conditioning of the plant stem. The use of the steel-on-steel intermeshing roll design ensures that leaves are retained for high protein value, providing high-quality hay, forage, and alfalfa crops. The straight design of these conditioner rolls makes them easy to repair, as damaged sections can easily be cut out and replaced.

The rolls are powered by a hydraulic motor with an adjustable speed from 601 rpm to 790 rpm. The steel rolls offer improved wear life, particularly in adverse soil and crop conditions.

Optional reverser clears plugs effortlessly for higher productivity during tough harvest conditions

Platform reverser controls on W155

Platform reverser controls on W155

Platform reverser controls are available for the W155 Self-Propelled Windrower only:

- Easily activated from operator's station to clear platform of plugs

- Reverser slowly reverses the knife drive and optional hay conditioner, if equipped, to clear plugs

- Highly recommended when using optional hay conditioner with 400D Platforms

- Operators can run machines closer to their maximum capacity and it will take less time to unplug

Reverser valve block

Reverser valve block

The reverser consists of a valve block and valves, shown in the image above. It is the gold-colored valve block on the right side. It is shown plumbed for a 100A Auger Platform.

Rock-drop opening protects conditioner rolls

Drop-out area

Drop-out area

Located below the auger and in front of the conditioner rolls, the rock-drop opening allows rocks and other obstructions to drop out before reaching the conditioning rolls while still ensuring proper crop flow. The rock-drop feature helps to protect the platform's internal components from damage, which will increase uptime and productivity. It also allows sand, soil, and debris to drop out below the windrow for higher-quality crop and less foreign material in the windrow.